In the modern world of highly sensitive manufacturing, from medical device production to microelectronics assembly, the choice of protective handwear is non-negotiable. It’s not just about compliance; it’s about product integrity. Among the array of options, White Nitrile Gloves stand out as the preferred solution, particularly for demanding environments like clean rooms. These gloves offer a unique combination of exceptional cleanliness, high durability, and superior puncture resistance that far surpasses traditional latex or vinyl alternatives.

This comprehensive guide delves into why White Nitrile Gloves have become the industry standard for controlled environments, focusing on their specific applications, inherent strengths, and critical role in maintaining product quality.

I. The Essential Role of White Nitrile Gloves in Clean Rooms

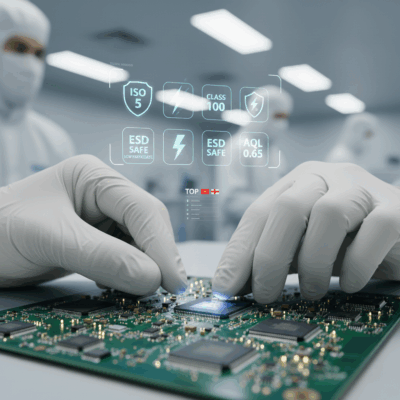

A clean room is defined by its rigorous control over airborne particulates, contaminants, and static electricity. Gloves used in this environment must not only protect the worker but, more critically, must prevent the worker from contaminating the product. White Nitrile Gloves meet this challenge through several key features:

1. Superior Cleanliness and Purity

The color white often signifies purity and is essential for visual inspection in contamination-critical areas. Beyond the color, the material itself is paramount:

- Powder-Free (PF): The most common form of clean room nitrile gloves is powder-free. Powder, used as a donning aid in traditional gloves, is a major source of particulate contamination. White Nitrile Gloves are rigorously processed (often through chlorination) to ensure they are powder-free, eliminating this contamination risk.

- Low Particle Count: High-quality White Nitrile Gloves are specifically washed with de-ionized (DI) water and processed in controlled environments to remove any manufacturing residue or loose particulates. This results in an extremely low particle count, making them suitable for ISO Class 5 (Class 100) and higher-level clean rooms.

- Low Extractable Ion Levels: In electronics and semiconductor manufacturing, trace metal ions can ruin sensitive components. White Nitrile Gloves offer minimal levels of extractable ions, providing a vital layer of protection against chemical contamination.

2. Hypoallergenic and Safe

Nitrile is a synthetic rubber, meaning it contains none of the proteins found in natural rubber latex. This makes White Nitrile Gloves an ideal choice for facilities concerned with latex allergies (Type I hypersensitivity), ensuring a safer working environment for all personnel.

II. Durability and Puncture Resistance: Built to Last

One of the most compelling reasons for the widespread adoption of Nitrile Gloves is their impressive physical performance. Unlike thin vinyl or even latex, nitrile offers a robust barrier, which is crucial when handling expensive or fragile components.

1. Exceptional Puncture Resistance

Nitrile inherently provides greater puncture resistance than latex or vinyl of the same thickness. This is vital in tasks involving sharp instruments, abrasive materials, or fine-tipped tools typical in clean room settings (e.g., handling semiconductor wafers or medical needles).

- Tear and Abrasion Resistance: The high tensile strength of nitrile means the gloves resist tearing during donning or high-stress movements, maintaining barrier integrity throughout the entire work session.

2. Chemical Resistance

In pharmaceutical and laboratory clean room environments, workers frequently handle mild chemicals, solvents, and cleaning agents. Nitrile provides good chemical resistance against a wide range of substances, often performing better than latex against many common lab chemicals. This added layer of protection keeps both the worker and the manufactured product safe from accidental exposure.

3. Superior Fit and Tactile Sensitivity

While durable, White Nitrile Gloves don’t compromise on feel. Once warmed by the hand, the material molds closely to the contours of the hand, providing excellent dexterity and tactile sensitivity. This allows workers to perform precision tasks—a non-negotiable requirement in micro-assembly and quality control—without fatigue or loss of feel.

III. Applications Where White Nitrile Gloves Excel

The unique properties of White Nitrile Gloves make them indispensable across several high-tech industries:

- Electronics and Semiconductor Manufacturing: The low particle count and inherent ESD (Electrostatic Discharge) properties of some specialized white nitrile gloves protect microchips and sensitive electronic assemblies from static damage and particulate contamination.

- Pharmaceutical and Biotechnical Industries: Sterility and cleanliness are paramount. White Nitrile Gloves (often Gamma irradiated for sterility) are used extensively in sterile compounding, laboratory testing, and drug manufacturing to prevent biological and particulate contamination.

- Medical Device Assembly: For components like catheters or surgical instruments, these gloves ensure that no lint, powder, or chemical residue is transferred to the final product.

- Aerospace and Optics: In assembly and cleaning procedures for high-precision optical instruments or satellite components, the non-shedding, powder-free nature of the gloves is mandatory.

IV. Choosing the Right White Nitrile Gloves for Your Needs

To ensure maximum product protection and workplace safety, companies must look beyond the generic term “nitrile glove.” When selecting your vật tư phòng sạch (clean room supplies), consider the following:

- Certification: Look for compliance with international standards such as ISO Class (e.g., ISO 5, ISO 6) or ASTM standards for barrier integrity and puncture resistance.

- Cuff Length: Longer cuffs (12 inches or more) provide better overlap with clean room garment sleeves, offering a more secure barrier against contamination.

- Thickness: While all nitrile is tough, slightly thicker gloves (e.g., 5-mil) offer even better durability and puncture resistance for heavy-duty tasks, whereas thinner gloves (e.g., 3-mil) prioritize tactile sensitivity.

Conclusion

White Nitrile Gloves are more than just a piece of personal protective equipment; they are a critical component of contamination control strategy. Their unique combination of durability, superior puncture resistance, and unparalleled cleanliness makes them the optimal choice for any demanding clean room or controlled environment. By preventing contamination and static damage while offering a comfortable, high-dexterity fit, these gloves ensure consistent product quality and operational excellence across the high-tech, medical, and manufacturing sectors.

Investing in high-quality White Nitrile Gloves is an investment in the long-term success and integrity of your product line. They are the clean, tough, and reliable barrier your sensitive products need.