In the fast-paced world of manufacturing and hygiene control, nitrile gloves have become an essential part of safety and precision work. Whether in healthcare, laboratories, or electronic components manufacturing, the right choice of gloves can greatly impact product quality, worker safety, and process efficiency.

In this guide, we’ll explore what makes nitrile gloves superior, how to choose the best type for your application, and why Thai Hoa Gloves — a leading manufacturer in Vietnam — is trusted by many global electronics producers for cleanroom and ESD-safe gloves.

1. What Are Nitrile Gloves and Why Are They Essential?

Nitrile gloves are made from nitrile butadiene rubber (NBR), a synthetic material designed to resist punctures, oils, and chemicals. Unlike latex gloves, nitrile gloves are latex-free, eliminating allergy risks while offering exceptional strength and flexibility.

In industries like electronics manufacturing, nitrile gloves are essential because they:

- Prevent contamination of sensitive components.

- Reduce electrostatic discharge (ESD) risks that can damage microchips.

- Maintain cleanroom hygiene by minimizing particle shedding.

- Provide a secure grip for handling small, delicate parts.

This combination of safety, cleanliness, and precision makes nitrile gloves indispensable in high-tech environments.

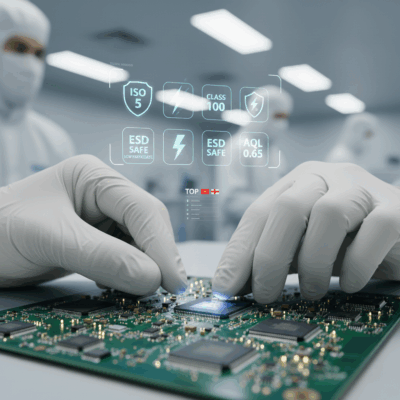

2. Why Nitrile Gloves Are Ideal for Electronic Components Manufacturing

The electronics industry requires strict control of static electricity, dust, and contamination. Workers handle micro-sized parts, semiconductors, and printed circuit boards (PCBs) — all of which are extremely sensitive to even the smallest contaminants.

Here’s why nitrile gloves are preferred over latex or vinyl:

a. Electrostatic Discharge (ESD) Protection

Static discharge can instantly destroy sensitive electronic components. High-quality nitrile gloves, especially ESD-safe versions, have low surface resistance, helping prevent electrostatic buildup.

b. Cleanroom Compatibility

Powder-free nitrile gloves are essential in cleanroom environments (Class 100–10000) because they release minimal particles. This ensures consistent product quality and reduces defects in semiconductor or PCB assembly lines.

c. Chemical Resistance

Nitrile gloves protect workers from contact with cleaning solvents, flux, or other chemicals commonly used in electronic production.

d. Comfort and Dexterity

Modern nitrile gloves provide a snug, ergonomic fit that allows workers to handle micro-components with precision — crucial for tasks requiring steady hands and tactile sensitivity.

3. Key Factors to Consider When Choosing Nitrile Gloves

Selecting the right nitrile gloves depends on your industry, usage frequency, and required protection level.

Here are the main criteria to consider:

a. Thickness

- Thin (3–4 mil): Ideal for light assembly and short-duration work in electronics.

- Medium (5–6 mil): Suitable for general handling and moderate chemical exposure.

- Thick (7–8 mil): Recommended for heavy-duty tasks or chemical cleaning.

b. Powder-Free Design

Always choose powder-free nitrile gloves for cleanroom use to prevent contamination of sensitive electronic parts.

c. Surface Texture

A micro-textured or fingertip-textured surface provides better grip, especially when handling small components or tools.

d. Color

Blue and white nitrile gloves are common in electronics manufacturing for easy contamination detection and visual cleanliness.

e. Certifications

Ensure your gloves meet:

- EN 455 / EN 374 standards for protection and durability.

- ISO 9001 / ISO 13485 for manufacturing quality.

- ASTM D6319 for medical and industrial-grade nitrile.

- Cleanroom ISO Class certifications if applicable.

4. Thai Hoa Gloves — A Trusted Partner in Nitrile Glove Manufacturing

When it comes to reliability and performance, Thai Hoa Gloves has established itself as one of Vietnam’s leading nitrile glove manufacturers serving global industries, including electronics, medical, and cleanroom sectors.

Why Choose Thai Hoa Gloves:

- Advanced manufacturing technology: Automated production lines ensure consistent glove thickness and surface quality.

- International compliance: All Thai Hoa Gloves products meet FDA, CE, ISO, and ASTM standards.

- Cleanroom specialization: Offers low-particulate nitrile gloves suitable for electronic and semiconductor production.

- Eco-friendly processes: Thai Hoa Gloves emphasizes sustainability, using energy-efficient systems and biodegradable packaging.

- Global export network: Trusted by partners in Asia, Europe, and North America.

By combining quality assurance with cost-effective production, Thai Hoa Gloves provides a dependable solution for companies seeking stable glove supply chains for their electronic manufacturing needs.

5. How to Identify High-Quality Nitrile Gloves

Before purchasing, here are simple tests and checks to identify superior nitrile gloves:

- Stretch and Snap Test: Good nitrile gloves should stretch easily and return to shape without tearing.

- Visual Inspection: Look for uniform color and no visible defects or bubbles.

- Grip Test: Check the surface texture for slip resistance when handling smooth materials.

- Certification Labels: Only buy gloves with verified compliance marks and batch tracking.

Purchasing directly from a reputable manufacturer like Thai Hoa Gloves ensures consistent product quality, documentation, and reliable after-sales support.

6. Applications of Nitrile Gloves in the Electronics Industry

In the production of electronic components, nitrile gloves are used at multiple stages:

- Semiconductor wafer handling

- Printed Circuit Board (PCB) assembly

- Microchip testing and packaging

- LCD and LED module assembly

- Battery and connector production

Using cleanroom-grade nitrile gloves reduces contamination, protects components from electrostatic discharge, and maintains overall manufacturing integrity.

7. The Future of Nitrile Gloves in High-Tech Manufacturing

As the demand for smart devices, EV components, and microelectronics continues to grow, the need for premium nitrile gloves in cleanroom environments is rising rapidly. Manufacturers like Thai Hoa Gloves are investing in ESD-safe innovations and biodegradable nitrile technology to meet both environmental and industrial demands.

In the near future, we can expect nitrile gloves that combine:

- Enhanced ESD protection

- Better tactile sensitivity

- Sustainable production materials

These innovations will help maintain the balance between worker safety, product integrity, and environmental responsibility.

Conclusion

Choosing the right nitrile gloves is critical for maintaining safety, precision, and cleanliness — especially in electronic components manufacturing. By focusing on glove thickness, material quality, ESD resistance, and certification standards, you can ensure maximum protection for both workers and sensitive devices.

If you’re looking for a trusted supplier that understands the strict requirements of high-tech industries, Thai Hoa Gloves offers certified nitrile gloves designed specifically for cleanroom and electronics applications.

Their commitment to quality, innovation, and sustainability makes Thai Hoa Gloves the ideal partner for your production line.