Introduction: The Non-Negotiable Standard in Electronics Assembly

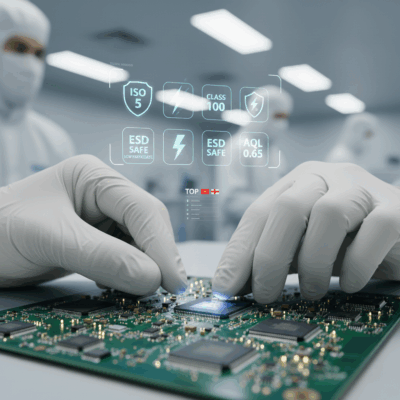

In the highly sensitive world of microchip manufacturing, PCB assembly, and delicate electronics production, the human hand is the largest source of contamination and electrostatic discharge (ESD) risk. For companies operating sophisticated cleanrooms, choosing the right hand protection is not a minor procurement decision—it is a critical factor in product yield, quality control, and regulatory compliance.

This guide focuses exclusively on High-Quality Industrial Nitrile Gloves designed for the stringent requirements of electronics cleanrooms. These gloves must not only be particle-free but also inherently ESD Safe to protect static-sensitive devices. We will explore the critical certifications, technical features, and process controls that define the industry standard, highlighting the commitment of specialized manufacturers like Thai Hoa Gloves to industrial excellence.

I. Focus on Precision: Why Industrial Nitrile is the Clear Choice

For electronics assembly, the required glove is purely an industrial and cleanroom consumable. It must excel in three core areas where traditional gloves fail: Particulate Control, Chemical Compatibility, and Static Dissipation.

A. The Requirement for Low-Contamination (Cleanroom Grades)

Cleanroom manufacturing, especially in electronics, demands gloves that meet strict particle and extractable limits, typically defined by ISO cleanliness classes (formerly US Fed. Std. 209E):

- ISO Class 5 (Class 100) & ISO Class 6 (Class 1,000): These are the most common grades required. High-quality nitrile gloves are manufactured, processed, and packaged in controlled environments, undergoing extensive washing (leaching) to achieve low non-volatile residue (NVR) and minimal ion counts (e.g., Sodium, Potassium). This ensures the glove material itself will not degrade and deposit corrosive substances onto delicate components.

- Powder-Free Design: All industrial cleanroom gloves must be powder-free to eliminate the risk of Corn Starch powder, a major particulate contaminant, being introduced into the controlled environment.

B. Inherent ESD Safety for Component Protection

Static electricity is an invisible killer of electronic components. The friction generated by a worker moving their hands or handling materials can build up a destructive charge. ESD Safe Nitrile Gloves are specifically formulated with static-dissipative polymers.

- Surface Resistivity: The glove’s material must have a surface resistivity within a specific range (often $10^9$ to $10^{11}$ ohms per square) to safely dissipate static charge without discharging it rapidly (which could still cause damage). This property is crucial for protecting modern microchips susceptible to damage from just a few hundred volts.

C. Enhanced Tactility and Chemical Resistance

Industrial nitrile gloves are engineered to be thin enough to maintain high tactile sensitivity—vital for handling tiny screws and wires—yet robust enough to resist common process chemicals, oils, and solvents encountered during manufacturing, such as IPA (Isopropyl Alcohol).

II. The Critical Certifications: ISO 9001 and ISO 14001

Unlike medical or food-grade gloves, which require specialized FDA or EN certifications, quality in the industrial cleanroom sector is proven through two core, globally recognized ISO management system standards.

A. ISO 9001: The Backbone of Quality Consistency

ISO 9001:2015 is the global benchmark for Quality Management Systems (QMS). For a cleanroom glove manufacturer, this certification is the guarantee of process consistency.

- What it Means for Customers: It ensures that every glove produced—from the raw nitrile compound to the final cleanroom packaging—follows the exact same, rigorously documented procedure. This consistency is essential in electronics, where slight variations in quality can lead to significant swings in production yield. ISO 9001 proves that the manufacturer, like Thai Hoa Gloves, is committed to continuous improvement and strict quality control on the factory floor.

B. ISO 14001: Commitment to Environmental and Supply Chain Integrity

ISO 14001 establishes the standards for an effective Environmental Management System (EMS). In the global electronics supply chain, this certification has become non-negotiable.

- Why It Matters to Electronics OEMs: Major multinational electronics companies require their suppliers to demonstrate environmental responsibility. ISO 14001 shows that the manufacturing process is designed to minimize waste, reduce energy consumption, and manage the disposal of chemicals and materials responsibly. For buyers choosing a partner, this certification confirms the manufacturer’s commitment to sustainable and ethical practices, aligning with global corporate social responsibility (CSR) goals.

III. Thai Hoa Gloves: Specializing in Cleanroom and ESD Solutions

Thai Hoa Gloves has strategically positioned itself as a focused manufacturer dedicated to the demanding needs of the high-tech and electronics industries. By eschewing the medical and food markets, they direct all their specialized resources toward industrial excellence.

A. A Focused Industrial Production Model

The manufacturing core of Thai Hoa Gloves is built around producing high-purity nitrile gloves specifically for cleanroom environments (e.g., Class 100 and Class 1000). Their facilities are designed with the strict process control required to meet the low-particulate and low-extractable specifications critical for microchip and electronics components.

B. Integrated Quality and Sustainability

The operation of Thai Hoa Gloves is underpinned by their dual commitment to management standards:

- Guaranteed Quality (ISO 9001): Every glove batch is manufactured under a certified QMS, ensuring that the critical ESD properties, tensile strength, and cleanroom washing procedures are uniform and reliable.

- Responsible Sourcing (ISO 14001): The commitment to a certified EMS ensures that their production footprint is responsible, a key assurance for global clients focused on green and ethical sourcing.

By choosing Thai Hoa Gloves, companies in the electronics assembly sector partner with a manufacturer whose quality framework (ISO 9001) and environmental management (ISO 14001) are perfectly aligned with their complex industrial and cleanroom requirements.

Conclusion: Securing Your Future with Certified Industrial Gloves

For companies in the high-tech, electronics, and precision manufacturing sectors, the choice of protective gear is an operational imperative. The market demands Industrial Nitrile Gloves that deliver a reliable triple threat: Low Contamination, ESD Safety, and Chemical Resistance.

By prioritizing manufacturers that adhere to the essential management standards—ISO 9001 for guaranteed quality and ISO 14001 for corporate sustainability—you secure a glove that is proven, consistent, and responsibly sourced. Thai Hoa Gloves embodies this dedicated approach, offering a specialized solution that meets the most critical needs of the modern electronics cleanroom without the distractions of medical or food-grade production. Secure your assembly line and your product yield by choosing gloves whose certifications reflect your uncompromising standards.

Industrial Nitrile Gloves, Cleanroom Electronics, ESD Safe Gloves, ISO 9001 Certified, ISO 14001 Compliant, Thai Hoa Gloves, Electronics Assembly, Cleanroom Consumables, Class 100 Gloves, PCB manufacturing, Static Dissipative Gloves.