1. Why Are Cleanroom Gloves Essential in Modern Manufacturing?

In industries such as electronics, healthcare, pharmaceuticals, and semiconductors, cleanroom environments play a critical role in maintaining purity, precision, and product quality.

Among the key consumables used in these environments, cleanroom gloves are indispensable.

Using high-quality cleanroom gloves not only protects sensitive products from dust, oils, and static discharge, but also safeguards workers and improves overall production efficiency.

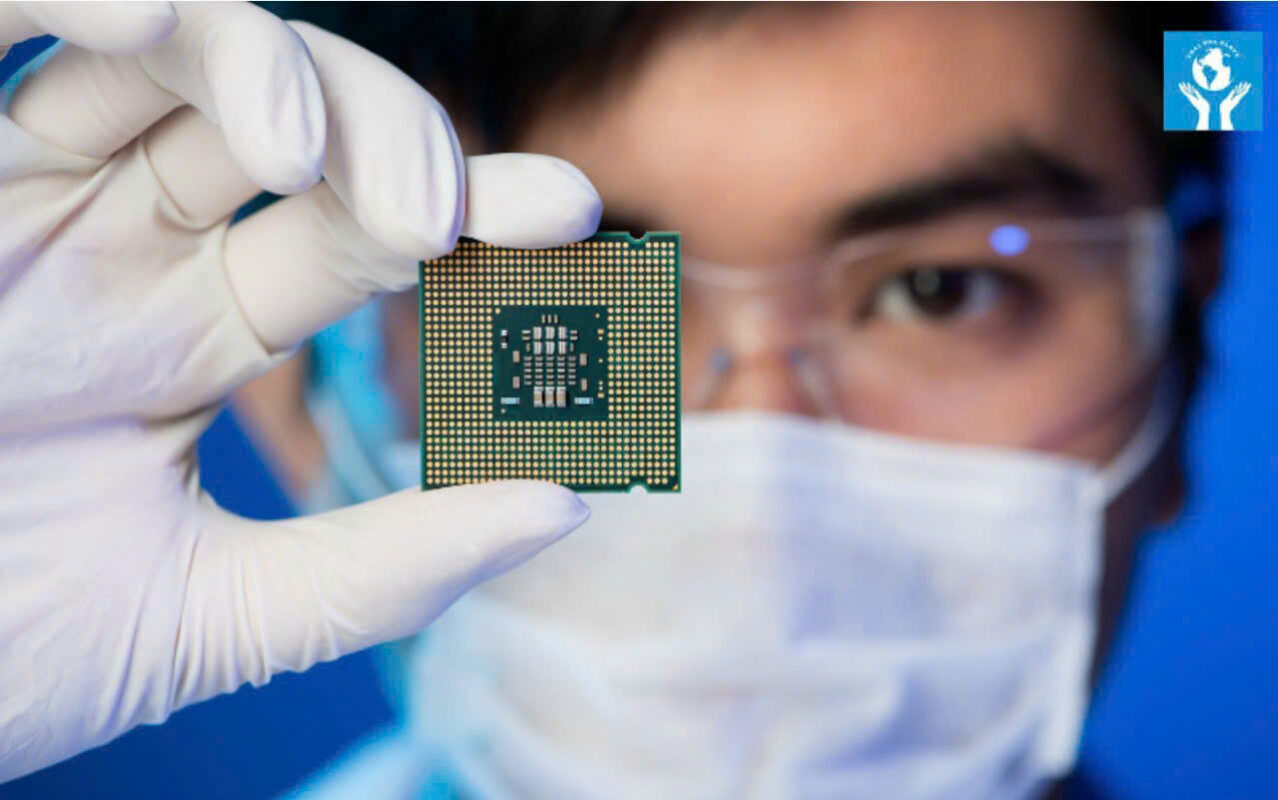

2. Ensuring Product Quality and Reducing Defects

Cleanroom gloves are designed to prevent contamination from micro-particles, sweat, or skin oils during handling — especially in electronics and semiconductor manufacturing, where even a tiny dust particle can cause product failure.

Using Class 100 to Class 1000 cleanroom gloves helps:

- Reduce airborne particles, dust, and ionic contamination.

- Keep surfaces clean and free from stains or residues.

- Increase product yield and consistency by reducing defects.

High-quality gloves also offer superior elasticity and tactile sensitivity, allowing operators to handle delicate components with accuracy and confidence.

3. Protecting Workers from Chemicals and Irritants

Besides protecting products, cleanroom gloves provide an important barrier for workers who may be exposed to chemicals, cleaning agents, or fine particulates.

Nitrile cleanroom gloves, especially powder-free types, offer several advantages:

- Chemical resistance against solvents and mild acids.

- Latex-free composition to prevent allergic reactions.

- Soft, comfortable texture for long working hours.

By providing reliable protection, high-quality gloves enhance worker safety and reduce occupational health risks.

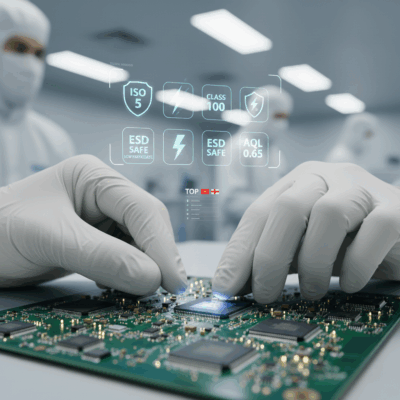

4. Preventing Electrostatic Discharge (ESD) in Electronics Production

One of the most serious risks in electronics manufacturing is electrostatic discharge (ESD), which can damage delicate circuits or PCBs.

ESD-safe cleanroom gloves help to:

- Neutralize surface charges, preventing static buildup.

- Protect ESD-sensitive components during assembly or inspection.

- Maintain stable surface resistance according to international standards.

That’s why ESD nitrile gloves are a must-have in cleanrooms handling microelectronics, sensors, and semiconductor devices.

5. Enhancing Corporate Image and Production Standards

Using high-quality cleanroom gloves reflects a company’s commitment to quality and professionalism. It enables manufacturers to:

- Meet strict requirements from international clients and OEM partners.

- Comply with ISO 14644, ISO 9001, and GMP standards.

- Strengthen brand reputation and customer trust.

In today’s competitive market, investing in quality materials helps companies stand out and expand globally.

6. Long-Term Cost Savings for Manufacturers

While premium cleanroom gloves may cost more initially, they deliver significant long-term savings by:

- Reducing defective products and rework costs.

- Minimizing maintenance expenses and equipment wear.

- Enhancing worker efficiency and safety.

This makes high-quality gloves a smart, cost-effective investment for sustainable manufacturing.

7. Thai Hoa Glove – Trusted Manufacturer of Cleanroom Gloves in Vietnam

With years of experience in nitrile glove production, Thai Hoa Glove is proud to supply:

- Class 100 – Class 1000 Nitrile Cleanroom Gloves

- ESD-Safe Nitrile Gloves

- Powder-Free Nitrile Gloves for sensitive environments

All products are strictly tested to meet international standards for cleanliness, tensile strength, and static control, ensuring safety and efficiency across cleanroom industries such as electronics, semiconductors, and healthcare.

Thai Hoa – The Only Cleanroom Glove Manufacturer in Vietnam

📞 Hotline: +84 982 832 915 – +84 986 154 291

📩 Email: info@thaihoagloves.com

🌐 Website: thaihoagloves.com

Fanpage: https://web.facebook.com/profile.php?id=61574859642766