In jobs that require meticulousness and high precision such as products – hand feel is the deciding factor in the quality of the operation.

1. What Is Surface Texture in Nitrile Gloves?

Surface texture refers to the micro patterns or roughness on the glove surface, usually created during the molding process to enhance grip and friction.

Depending on the working environment, Nitrile gloves are designed with different texture patterns:

- Finger-textured: Improves grip when handling small or delicate items.

- Palm-textured: Provides better control when holding larger objects.

- Fully textured: Offers maximum grip in oily, wet, or slippery conditions.

These textures not only prevent slipping but also affect the tactile sensitivity and precision of the wearer during detailed work.

2. How Texture Affects Tactile Sensitivity

🔹 Maintaining a Natural Touch Feel

A high-quality Nitrile glove maintains a natural touch sensation, even with added texture.

The fine micro-patterns are engineered to improve friction without reducing the user’s ability to feel surface details, temperature, or object shape.

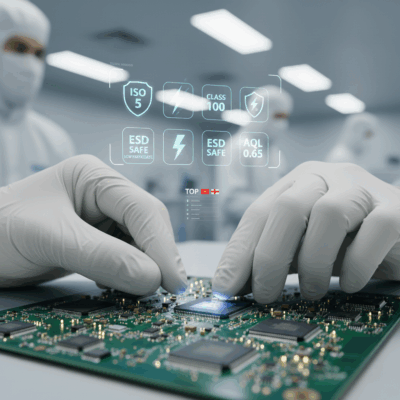

This is especially important for electronics assembly, micro-component handling, or laboratory work, where every movement requires absolute precision.

🔹 Non-slip yet Flexible

A properly designed textured surface provides better grip control without making the glove feel rigid or rough.

If the texture is too aggressive, it can cause discomfort and reduce hand flexibility. That’s why professional-grade Nitrile gloves feature a balanced texture — ensuring secure grip, comfortable wear, and natural movement, even during long shifts.

3. How Texture Affects Precision in Fine Handling

🔹 Enhanced Grip for Better Control

When working with tiny components such as screws, chips, or electronic parts, maintaining a firm grip is essential.

The micro-textured surface helps prevent slippage, especially in environments with moisture, sweat, or oil residue, allowing users to manipulate objects confidently and accurately.

🔹 Improved Force Control

With optimal texture, users can better control the amount of pressure applied when gripping objects — avoiding over-squeezing or losing control.

This precision is vital when working with fragile, delicate, or high-value components, minimizing errors and material loss.

🔹 Higher Efficiency and Consistency

Good tactile sensitivity and stable grip enable workers to perform tasks faster and more consistently. Over time, this not only improves productivity but also reduces fatigue and error rates in repetitive operations.

4. Thái Hoà Nitrile Gloves – Designed for Precision and Comfort

At Thái Hoà Glove, we are proud to be a leading Nitrile glove manufacturer in Vietnam, supplying high-quality products that meet international standards.

Our product range includes:

- Cleanroom Nitrile Gloves (Class 1000 certified)

- ESD Anti-static Nitrile Gloves

- Powder-free Textured Nitrile Gloves

- Gloves with full CO/CQ certification

Every glove is engineered to provide optimal surface texture, ensuring:

✅ Superior grip and control

✅ True hand sensitivity

✅ Comfortable fit and flexibility

✅ Reliable protection for professional environments

Whether in cleanroom electronics or precision manufacturing, Thái Hoà Nitrile Gloves are trusted for their consistent quality and ergonomic design.

5. Conclusion

The surface texture of a Nitrile glove is not just a visual detail — it’s a functional design feature that significantly impacts grip strength, tactile sensitivity, and work precision.

A properly textured glove allows workers to feel and handle small components accurately, without losing comfort or flexibility.

If you’re looking for premium-quality, powder-free, anti-static Nitrile gloves with ideal surface texture for your operations, choose Glorex Glove – your reliable partner for safe, clean, and efficient manufacturing.

Thái Hòa – Vietnam’s Sole Cleanroom Glove Manufacturer

📞 Hotline: 0982 832 915 – 0986 154 291

📩 Email: info@thaihoagloves.com

🌐 Website: thaihoagloves.com

Fanpage : https://www.facebook.com/glorexglove