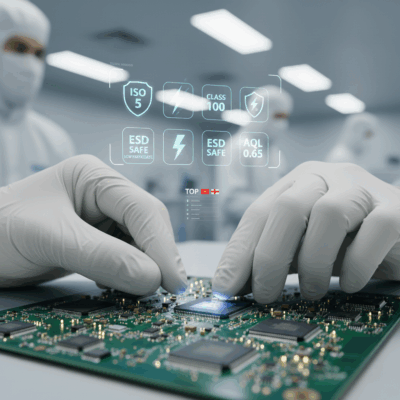

In the precision-driven world of semiconductor fabrication, biotechnology, and pharmaceutical manufacturing, the margin for error is non-existent. A single microscopic particle or a stray electrostatic discharge (ESD) can lead to catastrophic product failure. At the heart of this contamination control strategy is a critical piece of Personal Protective Equipment (PPE): Cleanroom Gloves.

Specifically, ISO Class 5 (Class 100) cleanroom gloves represent the gold standard for high-tech environments. This guide explores everything you need to know about selecting, using, and maintaining ISO Class 5 gloves to ensure maximum yield and safety.

1. Understanding ISO Class 5 Standards

To appreciate the quality of an ISO Class 5 glove, one must understand the environment it is designed for. According to ISO 14644-1, an ISO Class 5 cleanroom allows no more than 3,520 particles (sized 0.5µg or larger) per cubic meter of air.

The Technical Requirements for Gloves

Gloves destined for these environments must undergo rigorous “laundering” in deionized (DI) water and be packaged in a controlled environment. Unlike standard medical or industrial gloves, ISO Class 5 gloves are:

- Low in Particulates: Tested via Liquid Particle Count (LPC) to ensure they don’t shed fibers or fragments.

- Low in Extractables: Minimal levels of trace elements like Silicone, Sodium, or Potassium that could contaminate sensitive surfaces.

- A-pyrogenic/Sterile (Optional): If used in life sciences, they may also need to be Gamma-irradiated.

2. Material Matters: Why Nitrile Dominates ISO Class 5

While cleanroom gloves come in Latex, Vinyl, and Polychloroprene, Nitrile is the industry preferred material for ISO Class 5 protection.

Benefits of Nitrile Cleanroom Gloves:

- Superior Cleanliness: Nitrile is inherently cleaner than Latex, which contains natural proteins that can cause allergies and contaminate micro-environments.

- Chemical Resistance: They offer excellent protection against IPA (Isopropyl Alcohol), acids, and various solvents commonly used in cleaning wafers or lab equipment.

- Durability: Nitrile provides high puncture resistance, reducing the risk of a “breach” in the cleanroom barrier.

- ESD Properties: Nitrile is naturally static-dissipative, making it ideal for the electronics industry where electrostatic discharge is a major concern.

3. Key Features to Look for in ISO Class 5 Gloves

Not all “cleanroom” gloves are created equal. To ensure you are truly getting ISO Class 5 protection, look for these specific technical features:

3.1. 12-Inch (300mm) Extended Cuff

In an ISO 5 environment, the gap between the glove and the cleanroom suit (bunny suit) is a major contamination risk. A 12-inch cuff allows the glove to be pulled securely over the sleeve, ensuring that skin cells and arm hair remain trapped inside the garment.

3.2. Textured Fingertips

Handling silicon wafers or micro-pipettes requires extreme dexterity. Most ISO 5 gloves feature a micro-textured surface at the fingertips to provide a secure grip, even when working with wet or oily components.

3.3. Cleanroom Laundering and Packaging

ISO Class 5 gloves must be washed in multistage DI water systems and vacuum-packaged in “Double Bag” configurations. This allows the operator to remove the outer bag in a staging area and bring only the pristine inner bag into the core cleanroom.

4. Comparison Table: ISO Class 5 vs. Standard Gloves

| Feature | Standard Industrial Gloves | ISO Class 5 (Class 100) Gloves |

| Particle Count | Not measured | Extremely Low (LPC Tested) |

| Extractable Ions | High (Sodium/Chloride) | Minimal (DI Washed) |

| Packaging | Cardboard boxes | Double-bagged in poly-bags |

| Powder | Often powdered/lightly powdered | 100% Powder-Free |

| Manufacturing | Standard factory | Cleanroom Environment |

5. Critical Applications for ISO Class 5 Protection

Where exactly is this level of protection required? The applications are diverse but share a common need for ultra-cleanliness.

- Semiconductor & Microelectronics: Preventing ionic contamination and ESD damage to nanometer-scale transistors.

- Pharmaceutical & Biotech: Protecting sterile compounds from human-borne bacteria and particles.

- Aerospace & Defense: Assembly of sensitive optical instruments, lenses, and satellite components.

- Medical Device Manufacturing: Ensuring implants and surgical tools are free from pyrogens and particulates before sterilization.

6. Best Practices for Donning and Handling

Even the best ISO Class 5 glove will fail if the donning procedure is flawed. Follow these steps to maintain integrity:

- Pre-wash: Wash hands thoroughly to remove oils and skin fragments before entering the gowning area.

- The “No-Touch” Technique: Avoid touching the exterior “working” surface of the glove (the fingers and palm) with your bare hands during the donning process.

- Check for Tears: Inspect each glove for pinholes or tears before entering the critical zone.

- Regular Changes: In ISO 5 environments, gloves should be changed every 2–4 hours or whenever they become soiled or compromised.

7. How to Optimize Your Supply Chain for Cleanroom Gloves

To ensure your facility always meets ISO 14644-1 standards, consider these procurement tips:

- Demand a Certificate of Analysis (CoA): Every lot of ISO Class 5 gloves should come with a CoA documenting the particle count and extractable levels.

- Evaluate “Accelerator-Free” Options: For workers with sensitive skin, accelerator-free nitrile gloves reduce the risk of Type IV allergies (Contact Dermatitis).

- Sustainability: Look for manufacturers that offer glove recycling programs to reduce the environmental impact of these single-use items.

Conclusion

The ISO Class 5 cleanroom glove is more than just a hand covering; it is a precisely engineered tool designed to protect the future of technology and medicine. By choosing the right material, verifying technical specifications like LPC and ESD, and adhering to strict donning protocols, you can ensure your controlled environment remains truly “clean.”

As manufacturing becomes increasingly miniaturized, the demand for high-quality protection like that offered by Thai Hoa Nitrile Gloves and other industry leaders will only grow.

❓ Frequently Asked Questions (FAQ)

Q: Can ISO Class 5 gloves be reused? A: No. In almost all high-tech and pharmaceutical applications, these are strictly single-use to prevent cross-contamination.

Q: What is the shelf life of cleanroom nitrile gloves? A: When stored in a cool, dark place away from ozone and UV light, they typically have a shelf life of 3 to 5 years.

Q: Is “Powder-Free” the same as “Cleanroom Grade”? A: No. Many medical gloves are powder-free but still have high particle counts and ionic residues. Always look for the ISO Class rating.