In a controlled environment (cleanroom), selecting the right glove is a critical decision that impacts both product yield and worker safety. Whether you are operating in a semiconductor fab, a pharmaceutical lab, or a medical device manufacturing plant, understanding the nuances between Nitrile, Latex, and Vinyl is essential.

This guide provides a comprehensive comparison to help you choose the best protection for your specific cleanroom classification.

1. Why Material Selection Matters in Cleanrooms

Cleanroom gloves are more than just protective barriers. They are engineered to:

- Minimize Contamination: Low particle count and extractable levels.

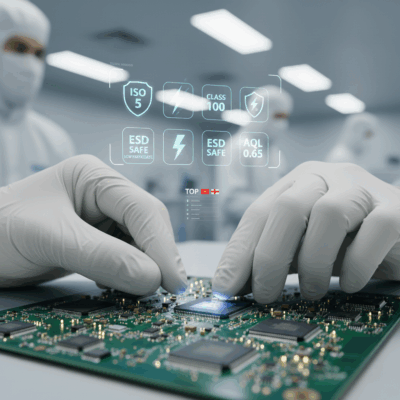

- ESD Protection: Prevent Electrostatic Discharge from damaging sensitive components.

- Chemical Resistance: Protect the wearer from solvents and acids.

- Comfort: Ensure dexterity for high-precision tasks.

2. Nitrile Cleanroom Gloves: The Industry Standard

Nitrile gloves are made from synthetic rubber (Acrylonitrile Butadiene). They have become the preferred choice for high-tech industries.

Key Benefits:

- Superior Durability: Highly resistant to punctures, tears, and abrasions.

- Chemical Resistance: Offers excellent protection against oils, greases, and many chemicals.

- Allergy-Free: 100% latex-free, eliminating the risk of Type I latex allergies.

- ESD Performance: Inherently dissipative properties make them ideal for electronics and semiconductor manufacturing.

Best For:

Microelectronics, biotechnology, and cleanrooms ranging from Class 10 (ISO 4) to Class 1000 (ISO 6).

3. Latex Cleanroom Gloves: The Classic Choice

Natural Rubber Latex (NRL) has long been favored for its unmatched tactile sensitivity and comfort.

Key Benefits:

- High Elasticity: Fits like a “second skin,” providing the best dexterity for intricate manual tasks.

- Biodegradable: An eco-friendly option compared to synthetic alternatives.

- Cost-Effective: Generally more affordable than high-end Nitrile.

Considerations:

- Allergy Risks: Can cause severe allergic reactions in sensitized individuals.

- Poor Oil Resistance: Degrades quickly when exposed to petroleum-based substances.

Best For:

Medical laboratories, pharmaceutical compounding, and general lab work where high precision is required.

4. Vinyl Cleanroom Gloves: The Economical Solution

Vinyl gloves are made from Polyvinyl Chloride (PVC). They are a popular choice for low-risk environments.

Key Benefits:

- Budget-Friendly: The most cost-effective option for high-volume usage.

- Static-Free: Naturally anti-static, though they lack the high-end ESD properties of Nitrile.

- Soft Feel: Provides a comfortable, loose fit.

Considerations:

- Lower Durability: High risk of “pinhole” leaks and tearing under stress.

- Limited Protection: Not suitable for handling hazardous chemicals.

Best For:

Food processing, assembly lines, and Class 10,000 (ISO 7) environments or higher.

| Feature | Nitrile | Latex | Vinyl |

| Material | Synthetic Rubber | Natural Rubber | PVC |

| Puncture Resistance | Excellent | Good | Moderate |

| Elasticity | High | Excellent | Low |

| Allergy Risk | None | High | None |

| Chemical Resistance | High | Moderate | Low |

| ESD Properties | Excellent | Fair | Moderate |

| Cost | Premium | Moderate | Budget |

Conclusion

The right glove depends on your cleanroom class, chemical exposure, and budget. For high-tech electronics, Nitrile is the undisputed winner. For maximum dexterity in labs, Latex remains a favorite, while Vinyl is perfect for simple, low-cost applications.