Electrostatic discharge (ESD) control is a critical factor in electronic component manufacturing.

A static discharge of just a few volts can damage microchips, shorten product lifespan, and cause significant losses for businesses.

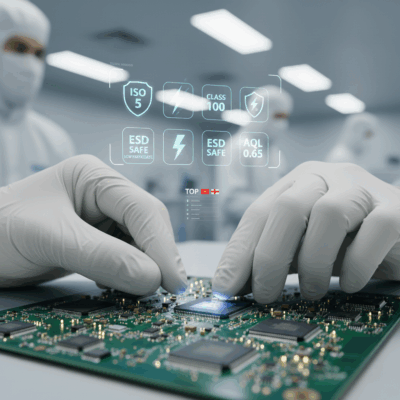

That’s why, in addition to controlling dust and microorganisms, many electronic cleanrooms enforce strict standards for anti-static equipment — and anti-static gloves are mandatory in certain sensitive areas.

1. What are anti-static gloves?

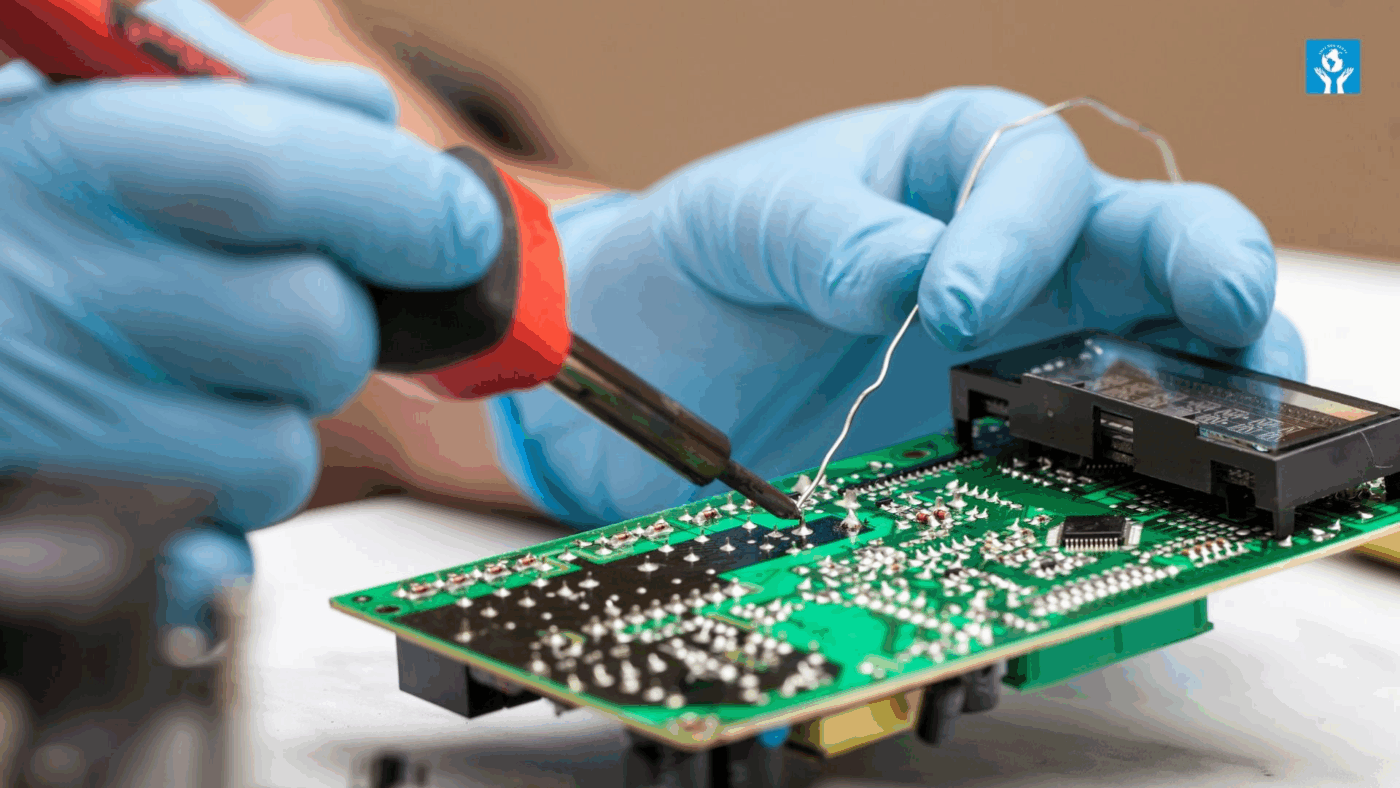

Anti-static gloves (ESD gloves) are made from materials capable of dissipating electrical charges. This prevents static electricity from accumulating on the glove surface, reducing the risk of sparks when handling sensitive components.

Unlike regular cleanroom gloves, which only block dust, sweat, and oil from human hands, anti-static gloves not only maintain cleanliness but also meet ESD safety requirements in production.

2. Why are anti-static gloves necessary in electronic cleanrooms?

- Protecting semiconductors and microchips: Components such as memory chips, transistors, and ICs are extremely sensitive. Even a small static discharge can cause short circuits, breakages, or reduced performance.

- Preventing production risks: Static electricity can lead to defective products, damage entire batches, and result in costly rework or scrapping.

- Compliance with international standards: Electronic manufacturing facilities often follow ANSI/ESD S20.20 or IEC 61340, which explicitly require the use of anti-static gloves for ESD control.

3. Why can’t regular cleanroom gloves be used instead?

- Regular cleanroom gloves only provide cleanliness by preventing contamination from dust, sweat, and oil from human hands.

- However, they cannot dissipate electrical charges, which means they may actually become a source of ESD when handling sensitive components.

- Therefore, in critical electronic production areas, regular cleanroom gloves are not safe enough and must be replaced with specialized anti-static gloves.

4. Why are anti-static gloves mandatory in certain areas of cleanrooms?

Not all areas in a cleanroom have the same requirements. Depending on the task and product sensitivity, the regulations vary:

- Semiconductor, chip, and microcircuit manufacturing: These are the most sensitive to ESD, making anti-static gloves mandatory.

- PCB and SMT assembly areas: A single discharge can damage solder joints, cause circuit failure, or reduce board stability.

- Electronic component storage and packaging areas: Without ESD control, components are at high risk of damage during storage and transportation.

- Testing and quality control (QA, QC): If finished products encounter ESD during testing, their entire value can be compromised.

On the other hand, in some supporting areas (hallways, offices within the facility, warehouses without sensitive components), regular cleanroom gloves may be sufficient.

5. Benefits of using certified anti-static gloves

- Enhanced product reliability: Minimize failures caused by ESD.

- Lower production costs: Reduce waste from damaged components.

- Meet customer and international partner requirements: Many global brands require suppliers to implement complete ESD control systems, with anti-static gloves as a basic element.

- Safer work environment: Reduce risks of sparks, short circuits, or ESD-related accidents.

6. Conclusion

In electronic cleanrooms, anti-static gloves are not just an option but a necessity in sensitive areas. They play a vital role in:

- Protecting electronic components from ESD risks.

- Ensuring product quality and reliability.

- Preserving the reputation and competitiveness of businesses in the global market.

👉 Therefore, when designing and operating electronic cleanrooms, companies must clearly distinguish: which areas only require standard cleanroom gloves, and which areas must use anti-static gloves to ensure maximum safety.