In high-precision and sterile industries like electronics manufacturing, pharmaceuticals, and scientific research, a single dust particle or an invisible static discharge can cause significant damage. To prevent these risks, cleanroom gloves have become an essential piece of protective equipment. They shield products from contaminants and ensure the absolute safety of the production process.

Why Are Cleanroom Gloves So Important?

Cleanroom gloves are more than just standard protective gear. They are designed and manufactured to meet the most stringent standards for the unique demands of a cleanroom environment. There are two primary reasons why they are so critical:

- Preventing Contamination from People Humans are a major source of contamination. Hair, dead skin cells, sweat, and dust from clothing can easily shed and attach to products. Cleanroom gloves act as an effective barrier, preventing these microparticles from coming into contact with sensitive components or materials.

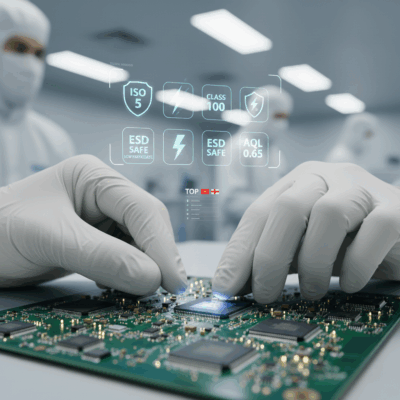

- Controlling Electrostatic Discharge (ESD) This is one of the most crucial functions of cleanroom gloves, especially in the electronics industry. Static electricity can build up on a person’s body and unexpectedly discharge when they touch a component. Although invisible to the naked eye, this discharge is powerful enough to destroy microcircuits, damage chips, and harm other delicate electronic parts. Cleanroom gloves are designed to dissipate this electrical charge, effectively controlling and eliminating this risk.

Types and Key Features of Cleanroom Gloves

The market offers a variety of cleanroom gloves, made from different materials to suit various applications. The three most common types are Nitrile, Latex, and Vinyl.

- Nitrile Cleanroom Gloves

- Features: These are the most popular type of gloves in modern cleanrooms. They are made from a synthetic rubber that does not contain the allergy-causing proteins found in Latex. Nitrile gloves are highly durable, puncture-resistant, and offer excellent chemical resistance.

- Advantages:

- Powder-Free: Eliminates the risk of contamination from glove powder.

- Good Anti-Static Properties: Some types are specially treated to enhance their anti-static capabilities.

- High Tactile Sensitivity: They fit snugly, providing a “true feel” that allows for precise manipulation, especially when handling small components.

- Applications: Electronics, semiconductor manufacturing, healthcare, pharmaceuticals, and laboratories.

- Latex Cleanroom Gloves

- Features: Made from natural rubber, Latex gloves are known for their excellent stretch and elasticity, providing a comfortable and secure fit.

- Advantages:

- High Elasticity: Allows for easy movement without restriction.

- Good Grip: Suitable for tasks that require a firm hold.

- Disadvantages: Can cause allergic reactions in some individuals due to latex proteins. They also have lower chemical resistance compared to Nitrile.

- Applications: Healthcare, surgery, and other industries requiring high tactile sensitivity.

- Vinyl Cleanroom Gloves

- Features: Made from synthetic PVC, Vinyl gloves are the most economical option. They offer moderate durability and are non-allergenic.

- Advantages:

- Low Cost: Ideal for jobs that do not require extremely high standards.

- Non-Allergenic: Safe for individuals with sensitive skin.

- Disadvantages: Less durable than Nitrile and Latex, prone to tearing and punctures. The fit is looser, providing less tactile sensitivity.

- Applications: Food processing, janitorial services, and low-risk tasks.

Important Cleanroom Glove Standards

To ensure quality and effectiveness, cleanroom gloves must comply with strict international standards, most notably ISO and ASTM.

- ISO 14001:2015: This standard focuses on environmental protection, including preventing pollution, minimizing waste, and using resources efficiently.

- ISO 9001:2015: This standard places the customer at the center of all operations, emphasizing the importance of understanding customer needs and expectations to deliver quality products and services.

How to Choose the Right Cleanroom Gloves

Selecting the correct type of gloves is crucial for optimizing work performance and ensuring safety. Here are a few useful tips:

- Identify the Working Environment:

- Electronics, Semiconductors: Choose anti-static, powder-free Nitrile gloves that meet ISO Class 100 or Class 1000 standards.

- Pharmaceuticals, Biology, Food Processing: Require sterile, non-allergenic gloves that meet high cleanroom standards. Regular, latex, or vinyl gloves may be suitable depending on the specific application.

- Research, Laboratories: Prioritize gloves with strong chemical resistance and high durability.

- Choose the Right Size: Gloves that are too loose will reduce precision, while gloves that are too tight will be uncomfortable, tear easily, and restrict blood flow.

- Check Certifications: Always buy products from reputable suppliers with international quality certifications.

- Proper Storage: Cleanroom gloves should be stored in a sealed, vacuum-packed container in a cool, dry place, away from direct sunlight and high temperatures.

In Conclusion

Cleanroom gloves are an indispensable component of industries that demand high precision and hygiene. They not only protect products from human-borne contaminants but also effectively control the risk of static discharge. Understanding the different types of gloves, their quality standards, and how to choose the right pair will help businesses optimize their production processes, enhance product quality, and ensure worker safety. Investing in high-quality cleanroom gloves is an investment in long-term success and reputation.