The Double-Edged Threat: Protecting Yield in Electronics Manufacturing

In the high-stakes environment of microelectronics, semiconductor, and sensitive component manufacturing, product integrity hinges on two critical factors: Particulate Control and Electrostatic Discharge (ESD) Control. Human hands, being the primary point of contact, are the biggest contributor to both airborne contamination and static charges.

Therefore, the choice of disposable gloves for electronics is arguably the most crucial decision in the cleanroom garment protocol. These gloves must perform flawlessly as a dual-protection barrier, safeguarding the multi-billion dollar yield from unseen threats.

This comprehensive guide delves into the essential technical requirements for disposable gloves in the electronics industry, focusing on how leading materials like Nitrile and specialized testing protocols ensure superior ESD safety and ultra-low particle release.

I. Particulate Control: Meeting the ISO Cleanliness Mandate

The primary function of a cleanroom glove is to prevent the shedding of particles, fibers, and extractable residues onto sensitive components. The material, processing method, and packaging are all subject to the rigorous ISO 14001 standards.

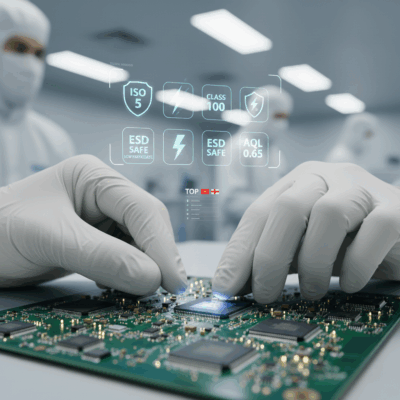

A. The Importance of ISO 5 (Class 100) Certification

For critical electronics fabrication, gloves must be certified for high-level cleanliness.

| ISO Class | Description | Application in Electronics |

| ISO 5 (Class 100) | Ultra-low particulate count | Wafer processing, Photolithography, Disk Drive Assembly |

| ISO 6 (Class 1000) | Low particulate count | PCB assembly, General microchip packaging |

Key Action: When purchasing disposable gloves for electronics, always verify that the product was processed and packaged in an environment meeting or exceeding the required ISO Class of your facility.

B. Testing for Residues and Ions (IEST-RP-CC005.4)

Particulate control goes beyond airborne fibers. Gloves must be tested for:

- Non-Volatile Residue (NVR): Chemicals or films left on components can interfere with bonding, coating, or soldering processes. Low NVR (< 10µg/cm²) is crucial for high-reliability applications.

- Ionic Contamination: Trace amounts of ions (especially Sodium (Na+), Potassium (K+), and Chloride (Cl–) can lead to metal corrosion or electrical defects. Ultra-pure water washing is often employed by manufacturers to ensure minimal ionic load.

II. ESD Control: The Essential Role of Dissipative Gloves

Static electricity is the silent killer in electronics. A discharge as low as 100 volts can damage modern microchips (Category C components). Therefore, the glove must be ESD Safe to prevent static charge accumulation and facilitate safe dissipation.

A. Understanding Surface Resistance

An effective ESD glove must be “dissipative,” meaning it allows charge to flow slowly and safely to a grounded surface (the wearer’s wrist strap and cleanroom garment).

- Insulative: Resists charge flow (e.g., standard latex). Unsafe.

- Conductive: Allows very rapid charge flow (risks rapid damage).

- Dissipative: Safely moves charge across the surface. Required.

The ideal Surface Resistance (Ω) for dissipative gloves used in electronics falls within the range specified by ANSI/ESD S20.20 and should be verified on the product datasheet.

10 5Ω < Surface Resistance} < 10 11Ω

B. Why Nitrile is the Preferred ESD Material

While natural rubber latex is an insulator, modern Nitrile gloves are specially formulated with conductive additives (carbon or proprietary polymers) to achieve controlled static dissipation without contaminating the product. This makes Nitrile ESD Safe disposable gloves the de facto standard for the industry.

III. Barrier Integrity and Performance (ASTM Standards)

Beyond cleanliness and ESD, the glove must offer physical protection without compromising dexterity. ASTM standards govern these mechanical properties.

A. Acceptable Quality Limit (AQL)

AQL is the most direct measure of a glove’s barrier integrity (freedom from pinholes). For electronics manufacturing, where product failure is expensive, only low AQL values are acceptable.

| AQL Value | Quality Implication | Recommended Use in Electronics |

| AQL 2.5 | Standard Industrial Grade | Non-critical areas/Packaging |

| AQL 1.5 | High Examination Grade | Standard PCB Assembly, Less Critical QC |

| AQL 0.65 | Ultra-Cleanroom Grade | Semiconductor Fabrication (ISO 5), Critical Device Handling |

Recommendation: Opt for a glove with an AQL of 1.5 or lower. The higher cost of AQL 0.65 gloves is often justified by the value of the components being handled.

B. Dexterity and Comfort

Electronics assembly involves repetitive, fine motor tasks. Gloves must:

- Fit Snugly: Minimize material bunching and enhance tactile feedback.

- Be Thin: Thinner materials (e.g., 4.0 mil) are often preferred, provided they retain adequate puncture resistance (ASTM D6319).

- Offer Textured Fingertips: Provides enhanced grip when handling smooth, small components.

IV. Selection Guide: The Ideal Disposable Glove for Critical Electronics

When sourcing disposable gloves for electronics manufacturing, look for a product that checks all the following boxes:

- Material: Nitrile (100% Powder-Free) for chemical and allergy safety.

- Cleanliness: ISO 5 (Class 100) or ISO 6 (Class 1000) processed.

- ESD: Explicitly labeled ESD Safe and verified to be within the dissipative resistance range (10 5Ω to 10 11Ω).

- Quality: AQL ≤ 1.5 (ideally AQL 0.65).

- Length: 12-inch cuff length recommended for proper overlap with cleanroom gowns.

Conclusion: Investing in Quality, Not Just Cost

The small cost difference between an uncertified disposable glove and a fully certified ESD Safe, ISO 5 Nitrile glove is minuscule compared to the potential loss from contamination or ESD failure in electronics production. Choosing certified gloves is not an overhead expense; it is a fundamental investment in manufacturing yield, product quality, and compliance with rigorous international standards.

By prioritizing gloves with verifiable ESD control and ultra-low particulate release, you install the best possible last line of defense against the unseen threats in your cleanroom.

Ready to secure your critical supply? Click here to find the best bulk deals on certified ESD Nitrile Gloves and ensure fast shipping today!