Introduction: The Invisible Threat in High-Tech Manufacturing

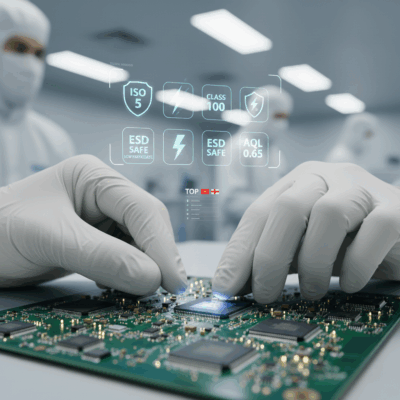

In the highly specialized world of semiconductor fabrication, microelectronics assembly, and pharmaceutical packaging, cleanliness is paramount. Yet, another critical, often invisible enemy lururks: Electrostatic Discharge (ESD). A static charge, built up by friction on a worker’s body or clothing, can instantly destroy sensitive electronic components (ESDs) like microchips, microprocessors, and circuit boards, often before the damage is visible to the naked eye.

The hands of an operator are the primary point of contact with these delicate components. Therefore, standard cleanroom gloves are simply not enough. Industries require ESD Cleanroom Gloves—specialized hand protection designed not only to control particulate contamination but also to safely dissipate static electricity. This comprehensive guide explores the science behind ESD damage, the technical requirements for ESD gloves, and why they are the essential barrier for maintaining both product yield and integrity in any ESD Protected Area (EPA).

I. Understanding ESD: The Silent Killer of Electronic Components

ESD occurs when two objects with different electrical charges come into contact, transferring charge rapidly. In manufacturing, this event is often caused by the movement of people (tribocharging) or the handling of non-conductive materials.

A. The Mechanism of ESD Damage

Electronic components are becoming increasingly smaller and more sensitive. Modern devices can be damaged by voltages as low as 100 volts, far below the human perception threshold (typically 2,000–3,000 volts). ESD events cause two main types of failure:

- Catastrophic Failure: The component is instantly destroyed, leading to immediate product rejection.

- Latent Failure: The component is partially damaged, functioning correctly during testing but failing prematurely in the field. This type of failure is far more costly and damaging to brand reputation.

B. Why Standard Gloves Are Insufficient

Standard gloves (even cleanroom-certified ones) made from non-conductive materials can actually act as insulators, trapping and allowing static charges to build up on the hand surface or inside the glove. When the hand touches a component, the discharge is amplified, directly harming the sensitive device. This makes specialized Anti-Static Gloves mandatory.

II. The Technical Requirements for ESD Cleanroom Gloves

An effective ESD cleanroom glove must serve a dual purpose: Contamination Control and Static Dissipation.

A. Static Dissipative Properties (The “ESD Safe” Feature)

The core function of an ESD glove is to prevent charge build-up and safely dissipate any existing charge to the ground. This is achieved through proprietary polymer formulations that modify the glove’s electrical properties.

- Surface Resistivity: This is the key measurement. High-performance ESD gloves must have a surface resistivity within the Dissipative Range (typically $10^9$ to $10^{11}$ ohms/square). This range ensures the charge is dissipated slowly and safely, preventing the rapid discharge event that causes component failure.

- Compliance Standards: Reputable ESD gloves must meet or exceed standards set by organizations like the ESD Association, such as ANSI/ESD S20.20 or ESD-S11.11.

B. Cleanroom Compliance

Because ESD events happen frequently within controlled environments (Cleanrooms), the gloves must simultaneously maintain ultra-low contamination levels.

- Low Particulate Count: The gloves must be powder-free and undergo rigorous washing (leaching) to remove manufacturing particulates, meeting cleanliness standards like ISO Class 5 (Class 100) or ISO Class 6/7.

- Low Non-Volatile Residue (NVR): Essential for preventing chemical residue or ions from contaminating product surfaces, especially in semiconductor lithography and deposition processes.

C. Material Choice: Nitrile as the Industry Standard

While other materials exist, Nitrile is the dominant choice for ESD cleanroom applications due to its inherent advantages:

- Durability: Excellent puncture resistance protects the barrier integrity.

- Chemical Resistance: Better protection against industrial solvents and process chemicals.

- Non-Allergenic: 100% Latex-free, ensuring operator safety and health.

III. Practical Benefits of Implementing ESD Cleanroom Gloves

Integrating high-quality Anti-Static Gloves into an EPA strategy yields tangible benefits that directly impact the bottom line.

1. Maximizing Product Yield

By eliminating the threat of latent and catastrophic ESD failure, manufacturers can significantly increase the percentage of components that pass final quality checks, directly boosting yield rates and profitability.

2. Ensuring Long-Term Reliability

Latent failures, caused by ESD micro-damage, are difficult and expensive to diagnose. Using certified ESD Safe Gloves ensures that the finished product maintains its intended lifespan, protecting the company from costly recalls, warranty claims, and reputation damage.

3. Streamlining Process Compliance

For companies selling products globally, demonstrating adherence to international ESD safety standards (like ANSI/ESD S20.20) is mandatory. Certified gloves simplify compliance documentation and reduce the risk of audit failure.

4. Improving Operator Comfort and Dexterity

Modern ESD nitrile formulations are engineered to be thin, providing exceptional tactile sensitivity—a necessity for handling tiny components—while maintaining a comfortable, non-binding fit for long shifts.

IV. Choosing the Right ESD Glove Supplier (A Focus on Quality)

When sourcing these critical components, manufacturers must partner with suppliers who focus exclusively on quality control and technical compliance.

- Look for Verification: Always request test data showing the glove’s Surface Resistivity and Cleanroom Class certification.

- Source Stability: The consistency of the ESD additive is crucial. Manufacturers with robust Quality Management Systems (like ISO 9001) ensure that the static dissipative properties are uniform across every batch.

Choosing a specialized supplier ensures that the gloves are consistently manufactured and packaged in a controlled environment, guaranteeing their dual functionality: being particle-free and static-dissipative.

Conclusion: The Essential Layer of Protection

In the high-stakes environment of advanced manufacturing, the investment in ESD Cleanroom Gloves is not merely a cost—it is an indispensable insurance policy against invisible damage. These gloves provide the final, critical layer of defense, ensuring that the human interaction necessary for assembly and handling does not compromise the purity of the cleanroom or the functionality of the sensitive components.

By prioritizing certified, high-quality ESD nitrile gloves, companies secure the integrity of their products, maximize production yield, and ensure full compliance with global industry standards. Make the intelligent choice: protect your products with the specialized barrier they deserve.

ESD Cleanroom Gloves, Anti-Static Gloves, Static Dissipative Nitrile Gloves, Cleanroom Gloves for Electronics, ESD Damage Protection, ANSI/ESD S20.20, Semiconductor Manufacturing, ISO Class 5 Gloves, Nitrile Gloves ESD Safe, Cleanroom Consumables.