In the modern industrial environment, frequent exposure to industrial chemicals, solvents, oils, and other hazardous substances is unavoidable. Protecting the hands, the most vulnerable point of contact, is more critical than ever. This is why Industrial Grade Nitrile Gloves have become an indispensable piece of Personal Protective Equipment (PPE).

This article will delve into why Nitrile gloves are the top choice for safeguarding hands against chemicals, and outline the key criteria for selecting high-quality products, including a mention of the reputable brand Thai Hoa Gloves.

1. Industrial Nitrile Gloves: Superiority and Key Advantages

Nitrile gloves are synthesized from Acrylonitrile Butadiene Rubber (NBR), a type of synthetic rubber. The biggest difference compared to Latex or Vinyl lies in Nitrile’s physical and chemical properties, making them ideal for heavy-duty industrial applications.

1.1. Excellent Chemical Resistance

This is the primary reason why Industrial Nitrile Gloves are favored. They offer superior resistance to permeation and degradation when exposed to a wide range of industrial chemicals, including:

- Oils, greases, and lubricants.

- Organic solvents like gasoline and diesel.

- Diluted acids and bases.

- Various cleaning agents and agricultural chemicals.

This capability is measured by the permeation rate (how quickly a chemical passes through) and degradation (the degree of material breakdown).

1.2. Mechanical Durability and Puncture Resistance

Compared to Latex gloves, Nitrile gloves offer significantly better puncture resistance and tear resistance, especially when used in mechanical, construction, or sharp object handling environments. They provide a high sense of security and durability in harsh working conditions.

1.3. Latex Allergy-Free

Since they are made from synthetic rubber, Nitrile gloves are completely free of natural Latex proteins, eliminating the risk of allergic reactions for users.

2. Diverse Applications of Industrial Nitrile Gloves

Nitrile gloves are widely used across various industries that demand stringent protection:

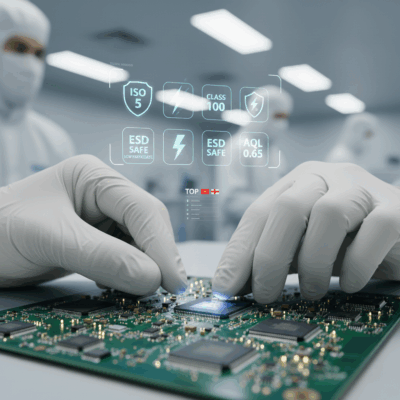

- Electronics/Semiconductor Industry: Powder-free, anti-static (ESD) Nitrile gloves are essential cleanroom supplies, protecting sensitive electronic components.

- Automotive/Mechanical Industry: Protecting hands from oils, brake fluids, and cleaning solvents.

- Chemical & Laboratory Sector: Handling solutions, diluted chemicals, and hazardous samples.

- Printing and Painting: Resisting ink and paint thinners/solvents.

- Industrial Cleaning: Protecting hands when using harsh cleaning chemicals.

3. Criteria for Selecting High-Quality Industrial Nitrile Gloves

To ensure maximum chemical protection effectiveness, users should pay attention to the following criteria:

- Thickness: Industrial gloves are typically thicker (5 mil and above) to increase the time needed for chemical breakthrough.

- Length: Longer cuff lengths (12 inches or more) help protect a portion of the forearm, especially when immersing hands in solvents.

- Quality Standards: They must meet international PPE standards like CE, ASTM, and chemical performance indicators such as EN 374 (chemical resistance performance).

- Grip: The surface is often designed with a rough or textured finish to enhance grip when hands are oily or working in wet environments.

- Powder-Free: Reduces the risk of contamination, which is particularly crucial in electronics and coating applications.

4. Thai Hoa Gloves: An Optimal Nitrile Glove Solution

In the competitive Nitrile glove market, the Thai Hoa Gloves brand stands out as a reputable supplier, specializing in products for the industrial and cleanroom sectors.

Thai Hoa Gloves focuses on delivering lines of Industrial Nitrile Gloves that meet stringent quality standards. Products from Thai Hoa Gloves are tested for barrier integrity and mechanical durability, addressing the protection needs in industries requiring high precision and exposure to industrial chemicals.

- Strengths of Thai Hoa Gloves:

- Excellent Quality-to-Price Ratio: Offering international standard products at optimal costs.

- Stable Supply Chain: Meeting the large-volume and frequent demand of manufacturing factories.

- Specialized Products: Providing Nitrile gloves of varying thicknesses, suitable for specific levels of chemical protection.

Businesses looking for cost-effective, durable, and high-quality Industrial Nitrile Glove solutions should consider the product lines from Thai Hoa Gloves to ensure absolute safety for their workforce.

Conclusion

Industrial Grade Nitrile Gloves are an irreplaceable protective barrier in workplaces exposed to hazardous chemicals. Selecting gloves must be based not only on price but also on strict standards for durability, thickness, and certified chemical resistance.

By using high-quality Nitrile Gloves, particularly trusted products like those from Thai Hoa Gloves, businesses can ensure maximum safety for their employees, thereby maintaining stable productivity and quality in the challenging industrial sector. Always prioritize products with high protective indices to truly achieve the goal of “Protection from Chemicals” effectively.