When choosing nitrile gloves, the three most important factors users consider are thickness, durability, and tactile feel during use. This trio is closely interconnected and directly impacts work efficiency.

1. Thickness and Durability – Directly Proportional

Thicker gloves lead to greater durability.

Increased thickness allows gloves to withstand more stress, making them less prone to punctures or tears during use. For example, 6–8 mil gloves offer significantly superior chemical resistance and puncture protection compared to 3–4 mil gloves.

However, thicker gloves have a drawback: they reduce flexibility, causing a stiffer feel during handling.

2. Thickness and Tactile Feel – Inverse Relationship

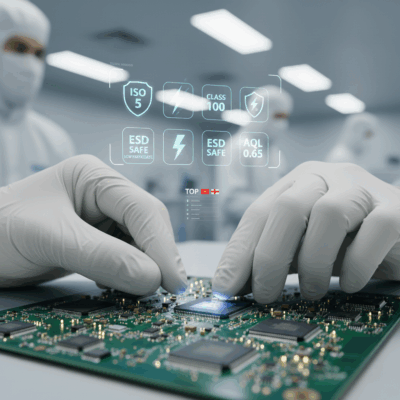

The thinner the glove, the more realistic the tactile feel. This is especially crucial for tasks requiring high precision, such as surgery, electronic component assembly, or laboratory research. However, thin gloves are more prone to tearing when stretched or exposed to sharp objects, compromising safety.

3. Durability vs. Dexterity – Finding the Balance

A durable glove isn’t necessarily effective if the wearer loses their sense of touch. Conversely, thin gloves offer good feel but frequent tearing leads to constant replacement, reducing productivity and increasing costs. Therefore, nitrile glove manufacturers (like Thai Hoa) constantly research to optimize thickness for both sufficient durability and comfortable handling.

4. Practical Application Illustration

Here’s how glove thickness translates to real-world applications:

- Healthcare: Prioritizing tactile sensitivity calls for 3-4 mil gloves.

- Electronics – Cleanrooms: A balance of flexibility and anti-static properties is achieved with 3-5 mil gloves.

- Food Processing – Light Industry: Opt for durability and comfort with 4-6 mil gloves.

- Heavy Industry – Chemicals: Emphasizing maximum durability and protection means choosing 6-8 mil gloves.

✅ In summary: There’s an inherent trade-off between thickness, durability, and tactile feel. Businesses must clearly define their intended use to select the appropriate nitrile glove thickness, ensuring both worker safety and optimal productivity.

👉 Let Thái Hòa Gloves be your partner with a diverse range of internationally certified nitrile gloves optimized for production efficiency.

Thái Hòa – Vietnam’s Sole Cleanroom Glove Manufacturer

📞 Hotline: 0982 832 915 – 0986 154 291

📩 Email: info@thaihoagloves.com

🌐 Website: thaihoagloves.com