Redefining Personal Protection Standards

In the era of Industry 4.0, safety and precision in the workplace are paramount. Protective gloves are not just a physical barrier but a key factor determining product quality and worker health. Among the available materials, Nitrile Gloves have quickly established their position as the most “Reliable Companion,” surpassing traditional materials like Latex and Vinyl.

This article will meticulously analyze the superior technical advantages, diverse applications, and the reasons why businesses should prioritize choosing Genuine Nitrile Gloves to ensure absolute performance and peace of mind. Specifically, we will explore the role of pioneering manufacturers in Vietnam, such as Thai Hoa Gloves, in providing stable, high-quality Nitrile solutions.

I. Technical Analysis: The Factors That Build Nitrile’s Reliability

The reliability of Nitrile gloves stems from their material structure and stringent manufacturing processes.

A. Superior Mechanical Durability and Puncture Resistance

Nitrile gloves are made from synthetic rubber (Acrylonitrile Butadiene), which provides impressive mechanical strength.

- Absolute Puncture Protection: Nitrile offers up to 3 times greater puncture resistance than Latex, protecting hands from sharp objects, needles, or fragments in medical, laboratory, and mechanical environments.

- Easy Fault Recognition: Unlike natural rubber (Latex), when a Nitrile glove is punctured, it tears immediately, clearly alerting the user that a replacement is needed, thereby minimizing the risk of contact with harmful substances or pathogens.

B. Effective Barrier Against Chemicals and Solvents

This is the key factor that makes Nitrile the preferred choice in heavy industries, electronics assembly, semiconductor manufacturing, and pharmaceuticals.

- Resistance to Oils, Greases, and Organic Solvents: The polymer structure of Nitrile resists degradation by many types of industrial chemicals, oils, fuels, and cleaning solvents like alcohol, and dilute acids and bases. This ensures the glove maintains its barrier integrity throughout the work process.

- Laboratory Applications (Lab): Thanks to their diverse chemical resistance (certified according to EN 374 standard), Nitrile gloves are mandatory when handling biological samples and hazardous chemicals.

C. Health Safety: Non-Allergenic and Powder-Free

The biological safety factor makes Nitrile the new standard.

- Latex-Free: Nitrile is completely free of natural rubber latex proteins, eliminating the risk of Type I allergies (severe allergies) for both the wearer and the person being touched. This makes it suitable for all skin types, especially in electronics assembly, healthcare, and food processing environments.

- Powder-Free: High-quality Nitrile gloves contain no corn starch powder, preventing particle contamination in sensitive work environments like cleanrooms, operating rooms, or laboratories.

II. Multi-Industry Applications: From Healthcare to Electronics Manufacturing

The reliability and flexibility of Nitrile Gloves allow them to become essential items in many sectors:

A. Healthcare and Wellness

- Surgery and Dentistry: The absolute snug fit and high tactile sensitivity help doctors and dentists perform precise maneuvers, while the puncture resistance protects against cross-contamination.

- Pharmaceuticals and Testing: Ensures a sterile environment and protects the handler when dealing with biological compounds and chemicals.

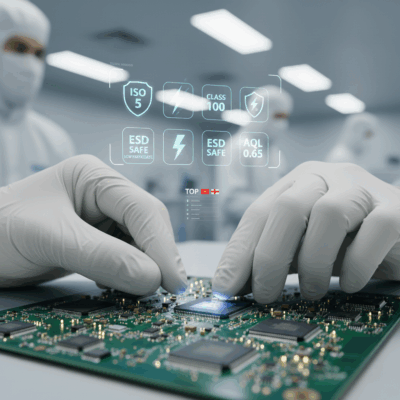

B. Industrial Manufacturing and Electronics Assembly (Cleanroom)

In the electronics component manufacturing industry, gloves must meet dual standards: cleanliness and anti-static properties.

- Cleanroom Nitrile Gloves: Meet ISO Class 5/6 (Class 100/1000) standards, having undergone rigorous washing (leaching) to remove ions, particles, and NVR (Non-Volatile Residue), ensuring no contamination of sensitive components.

- Anti-Static (ESD Safe): Specialized Nitrile lines have surface dissipation capabilities, protecting microcircuits and electronic chips from Electrostatic Discharge (ESD), which is a mandatory requirement during assembly.

C. Food Service, Aesthetics, and Spas

Nitrile gloves provide an absolute hygienic barrier, safe for contact with fresh food, grease, and cosmetic chemicals (dyes, tattoo ink, etc.).

III. Thai Hoa Gloves: Committing to High-Quality Reliable Companionship

Selecting a reputable supplier is the final step to ensuring you receive Genuine Nitrile Gloves with stable quality and optimal value.

A. Domestic Production Capacity with International Standards

Thai Hoa Gloves is a reputable brand in Vietnam, focused on manufacturing Nitrile gloves that meet international standards. Domestic production allows Thai Hoa to tightly control the manufacturing process according to standards such as:

- ISO 9001 & ISO 14001: Commitment to quality management and environmental responsibility.

- Strict Control: Durability testing, chemical resistance, and cleanliness levels (Cleanroom Class) are continuously performed, ensuring every box of gloves is uniform in quality.

B. Specialized Solutions for Vietnamese Industry

Thái Hòa particularly focuses on supplying specialized Industrial Nitrile Gloves, including ESD Safe and Cleanroom products capable of precisely meeting the technical demands of major electronics manufacturing groups in Vietnam.

Direct partnership with a capable manufacturer like Thai Hoa Gloves helps businesses:

- Stable Supply: Guarantees the ability to supply large, continuous quantities.

- Cost Optimization (Best Value): Eliminates intermediate costs, receiving the best price accompanied by certified quality.

- Technical Support: Receives in-depth consultation on selecting the appropriate glove type for the specific working environment (e.g., thin 3.5g gloves for better tactile sensitivity or thick 5.5g gloves for chemical resistance).

Conclusion: Enhancing Protection, Boosting Performance

Nitrile Gloves are more than just ordinary protective gear; they are a tool that helps enhance performance and provide absolute protection. Their resistance to puncture, chemicals, and non-allergenic properties have made them a Reliable Companion in every high-risk or purity-demanding job sector.

Investing in Genuine Nitrile Gloves from reputable suppliers like Thai Hoa Gloves is a strategic decision, ensuring that employees are protected in the safest manner possible, while maintaining the quality and purity of the final product. Choose Nitrile to turn safety into your competitive advantage.