Introduction: The Non-Negotiable Need for Precision Protection

In the sensitive realms of semiconductor manufacturing, pharmaceutical production, aerospace technology, and medical device assembly, even the smallest contaminant or electrostatic discharge (ESD) event can lead to catastrophic product failure, compromised research, or millions in losses. The hands of your operators are both your most valuable asset and your greatest potential source of contamination.

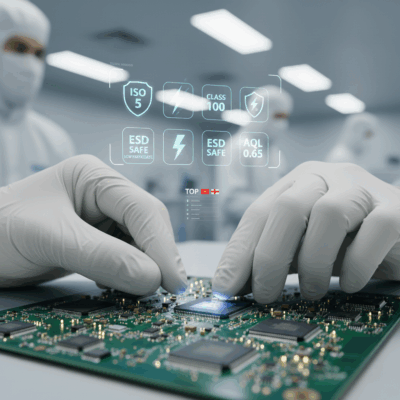

This is where the specialized world of cleanroom nitrile gloves intersects with the critical demand for ESD safe protection. These are not merely disposable gloves; they are a sophisticated, non-shedding, and compliant barrier designed for the most demanding controlled environments. This comprehensive guide explores why nitrile gloves are the gold standard, the science behind their ESD properties, and how a leading manufacturer like Thai Hoa Gloves is setting the benchmark for quality and performance.

I. Why Nitrile is the Superior Choice for Cleanrooms

Latex, vinyl, and other materials have their place, but in a certified cleanroom (ranging from ISO Class 3 to ISO Class 7), nitrile gloves offer an unparalleled combination of benefits that address every major risk factor:

A. Low Particulate and Extractable Counts

A glove’s primary enemy in a cleanroom is particle shedding. Nitrile, a synthetic polymer (acrylonitrile-butadiene rubber), is inherently cleaner than natural latex. High-quality cleanroom nitrile gloves undergo rigorous washing and chlorination processes to remove manufacturing residues, particulates, and ion contaminants. This results in low-NVR (Non-Volatile Residue) and low-ion gloves that comply with stringent standards like IEST-RP-CC005.4, ensuring they will not contribute to the contamination load of your critical process.

B. Superior Chemical and Puncture Resistance

Cleanroom operations often involve handling various solvents, acids, and other process chemicals. Nitrile provides significantly better chemical resistance compared to latex or vinyl, offering a safer barrier for the user’s skin and preventing chemical permeation. Furthermore, the material’s excellent puncture resistance adds an extra layer of protection, reducing the risk of a breach that could expose both the product and the operator to harm.

C. Allergen-Free Composition

Nitrile is entirely latex-free, eliminating the risk of Type I (immediate) latex protein allergies. For a workforce donning and doffing gloves multiple times a day, this is a crucial occupational health benefit, ensuring a safer and more comfortable working environment.

II. The Critical Requirement: ESD Safety in Cleanroom Gloves

Electrostatic Discharge (ESD) is an invisible threat. A static charge built up on a worker’s body, even if below the threshold of human sensation, can instantly destroy sensitive electronic components like microchips, hard drives, and microprocessors. For this reason, ESD-safe gloves are mandatory in EPA (ESD Protected Areas) within the cleanroom.

A. How Nitrile Gloves Achieve ESD Compliance

While standard nitrile is naturally dissipative, specialized ESD nitrile cleanroom gloves are formulated with proprietary additives to enhance their conductive or dissipative properties. This modification allows the glove to:

- Prevent Charge Build-up: It dissipates static charges before they can accumulate to a damaging level.

- Facilitate Grounding: When used in conjunction with a wrist strap and proper grounding, the glove helps to safely channel any residual charge away from the sensitive product.

The effectiveness of these gloves is typically measured by their Surface Resistivity (often in the range of $10^9$ to $10^{11}$ ohms per square) and must comply with standards such as ANSI/ESD S20.20 and ESD-S11.11. Choosing a glove specifically certified as ESD Safe is paramount for protecting devices susceptible to voltages as low as a few hundred volts.

B. Features of High-Performance ESD Nitrile Gloves

- Powder-Free & Non-Shedding: Minimizing particulates is key for both cleanroom and ESD integrity.

- Textured Fingers: Provides an excellent, non-slip grip for precision handling of small components.

- Extended Cuff (12″ or 16″): Offers increased coverage and protection up the wrist and arm, critical for cleanroom gowning protocols.

III. Meeting Global Demand: The Role of Thai Hoa Gloves

When sourcing critical consumables like cleanroom gloves, the manufacturer’s commitment to quality, process control, and compliance is everything. Thai Hoa Gloves has emerged as a respected manufacturer specializing in high-grade cleanroom and ESD-safe solutions, directly addressing the stringent needs of the global high-tech industry.

A. Commitment to Cleanroom Manufacturing Excellence

Located in Vietnam, Thai Hoa Gloves operates with state-of-the-art manufacturing processes designed to produce gloves with exceptional cleanliness. Their facilities and processes are engineered to meet international cleanroom standards, often producing gloves certified for use in:

- ISO Class 5 (Class 100): Required for the most critical operations, such as microelectronics and critical research.

- ISO Class 6 & 7 (Class 1,000 & 10,000): Suitable for general assembly, packaging, and less critical areas.

The focus on continuous process improvement and quality control ensures that every batch of Thai Hoa Nitrile Gloves provides consistent protection against particulates and static.

B. Specializing in Dual Protection: Cleanroom and ESD

Thai Hoa Gloves understands that the best solution offers dual functionality. Their product line emphasizes ESD Cleanroom Nitrile Gloves that deliver the low particle count required by the cleanroom while maintaining the surface resistivity needed for static control. This dual-purpose glove simplifies inventory, streamlines gowning procedures, and ensures maximum safety for both the product and the environment.

Key takeaway: When you choose Thai Hoa Gloves, you are selecting a solution that integrates particle control, chemical resistance, and static dissipation into a single, reliable barrier.

IV. Best Practices for Implementing ESD Nitrile Gloves

To maximize the efficacy and longevity of your cleanroom and ESD investment, follow these best practices:

- Proper Gowning Protocol: Always ensure the gloves are donned correctly over the cleanroom garment cuff to create a secure, overlapping barrier against skin and particle shedding.

- Regular Testing: Periodically test the surface resistivity of gloves from various batches to ensure consistent ESD performance, especially if dealing with ultra-sensitive components.

- Correct Sizing: A properly sized glove (snug but not restrictive) is essential for maintaining tactile sensitivity, which reduces the chance of dropped parts, and for ensuring the glove material is not overstretched, which can compromise its protective and ESD properties.

- Appropriate Storage: Store gloves in their original, sealed packaging in a cool, dry, and clean environment, away from direct sunlight, to maintain their integrity and ESD characteristics.

Conclusion: Securing Your Critical Environment with Confidence

The choice of protective handwear is a decision that directly impacts product yield, quality, and operator safety. Nitrile gloves for cleanroom environments are the definitive solution, offering an unmatched balance of chemical resistance, comfort, and minimal contamination.

By selecting specialized ESD safe nitrile gloves from a dedicated and compliant manufacturer like Thai Hoa Gloves, industries can secure the essential barrier required to operate with precision and confidence in their most critical environments. Invest in quality protection today—your product integrity depends on it.