Introduction: The Nitrile Revolution Replacing Traditional PVC Gloves

For decades, disposable protective gloves have been indispensable in healthcare, industry, and food service. PVC (Polyvinyl Chloride) gloves, also known as Vinyl gloves, were once a popular choice due to their low cost. However, advancements in material technology have propelled Nitrile Gloves (made from synthetic Acrylonitrile Butadiene rubber) to the forefront, setting a new benchmark for safety and performance.

This shift is not merely a trend; it is a necessary evolution based on technical superiority and safety factors. This article will provide a detailed analysis of the superior advantages of Nitrile gloves over PVC gloves, helping users and businesses understand why they should invest in a higher-quality protective solution to ensure absolute safety and work efficiency.

I. Core Differences: Material Structure and Mechanical Strength

The most significant disparity between these two glove types lies in their composition, leading to substantial differences in durability and protection capability.

A. Mechanical Durability and Puncture Resistance

This is the defining advantage of the Nitrile glove.

- Nitrile Gloves: Made from synthetic rubber, Nitrile gloves possess higher tensile strength and superior puncture resistance, 3 to 5 times greater than PVC. When punctured, Nitrile gloves typically tear immediately, forming a noticeable rip that is easy to spot. This mechanism allows the user to instantly detect the breach and replace the glove, minimizing the risk of cross-contamination or exposure to harmful chemicals.

- PVC/Vinyl Gloves: Made from a thermoplastic polymer, PVC gloves have low mechanical strength and are easily punctured or torn under stress. More concerningly, a puncture in a PVC glove often results only in a tiny pinhole, which is visually difficult to detect, significantly increasing the risk of unnoticeable exposure.

B. Chemical Resistance and Impermeability

For environments exposed to chemicals, Nitrile gloves provide a significantly more reliable protective barrier.

- Nitrile Gloves: Offer excellent chemical resistance, particularly against oils, greases, organic solvents, and many strong detergents. The dense molecular structure of Nitrile prevents the permeation of hazardous substances over a longer duration. This makes Nitrile gloves mandatory in laboratories, automotive industries, printing, and pharmaceutical manufacturing.

- PVC/Vinyl Gloves: Provide only basic protection against water and non-hazardous liquids. PVC gloves quickly degrade, stiffen, or become tacky when exposed to alcohol, organic solvents, or greases, causing them to lose their barrier integrity in a short period.

II. Differences in Health Safety and User Comfort

Beyond technical aspects, Nitrile gloves also offer clear benefits in terms of user health and operational experience.

A. Absolute Safety: Non-Allergenic Properties

The allergy factor is one of the primary reasons PVC and especially Latex gloves have been replaced.

- Nitrile Gloves: As a synthetic rubber, Nitrile is completely free of natural rubber latex proteins (Latex Free). This makes it an absolutely safe choice for all users, entirely eliminating the risk of Type I allergies (immediate reactions) associated with latex protein.

- PVC/Vinyl Gloves: Although Latex-free, PVC gloves are manufactured using plasticizers (Phthalates) to increase flexibility. Some studies have raised concerns about the leaching of these chemicals, particularly when exposed to oils or high temperatures, posing potential risks to user health and product integrity.

B. Fit, Dexterity, and Tactile Sensitivity

Work efficiency heavily depends on the feel of the glove while worn.

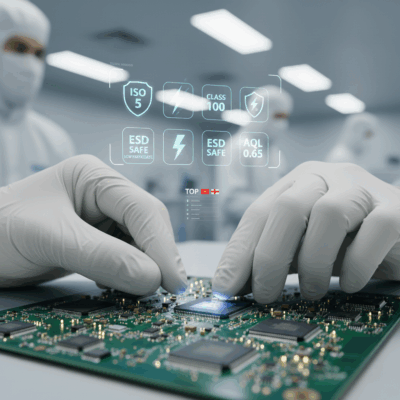

- Nitrile Gloves: Nitrile has a “memory” for body temperature. When worn, the glove gradually softens and conforms closely to the hand like a second skin, providing high tactile sensitivity. This allows users to perform tasks requiring high dexterity and precision, such as surgery, lab sampling, or electronics assembly.

- PVC/Vinyl Gloves: PVC gloves have low elasticity, often fitting loosely and poorly conforming to the hand. They provide a “clumsy” feel, significantly reducing tactile sensitivity and precision during operations, making them unsuitable for detailed work.

III. Specialized Applications and Long-Term Economic Benefits

While PVC gloves have a lower initial cost, when considering performance and replacement frequency, Nitrile gloves ultimately offer better long-term economic value.

A. Scope of Application

The technical superiority of Nitrile gloves ensures a wider and more reliable range of applications.

| Field | Nitrile Gloves (Optimal Choice) | PVC/Vinyl Gloves (Limited Use) |

| Healthcare/Laboratories | High puncture resistance, chemical barrier, and biological protection. | Only suitable for short-duration, low-risk tasks (e.g., dispensing medication). |

| Industrial/Mechanical | Oil/grease resistance, solvent resistance, high durability, abrasion resistance. | Degrade quickly upon contact with oil, not recommended for mechanical environments. |

| Food Service | Absolute barrier protection, non-allergenic, safe with oils and fats. | Suitable only for low-risk, raw food handling (minimal oil, low temperature). |

| Beauty/Tattooing | Durability, ink resistance, high precision for delicate work. | Quickly deteriorate when exposed to tattoo inks or chemicals. |

B. Economic Benefit and Cost-Efficiency

Despite their higher unit cost, Nitrile gloves are generally more durable and less prone to accidental tearing, allowing users to wear them for longer periods during a shift, thereby reducing replacement frequency. In contrast, PVC gloves’ low durability often necessitates frequent replacement, inadvertently increasing the total Cost-In-Use over time.

Conclusion: Investing in Safety is Investing in Performance

The detailed comparison clearly demonstrates that Nitrile Gloves are vastly superior to PVC/Vinyl Gloves in almost all critical aspects: mechanical durability, chemical resistance, skin safety, and tactile performance.

While PVC gloves retain a place for very low-risk tasks and budget-constrained environments, Nitrile gloves have become the gold standard in industries demanding stringent protection, such as healthcare, high-tech manufacturing, and laboratories. Choosing Nitrile gloves is a strategic decision—it is not only about protecting hands but also ensuring product quality and work efficiency in a professional setting.

Nitrile Gloves, PVC Gloves, Vinyl Gloves, Nitrile Advantages, Nitrile vs PVC Comparison, Chemical Resistance, Puncture Resistance, Non-Allergenic Gloves, Industrial Gloves, Medical Gloves, Latex Free, Protective Gloves.