The Unseen Threat: Why Standard Gloves Fail in Electronics

In the intricate world of electronics and semiconductor manufacturing, even the smallest contaminant or a silent electrostatic discharge (ESD) can render a circuit board or microchip useless. The human hand is the primary source of both particulates and static charge. Therefore, selecting the right cleanroom glove is not just an operational choice; it is a critical investment in product yield and quality control.

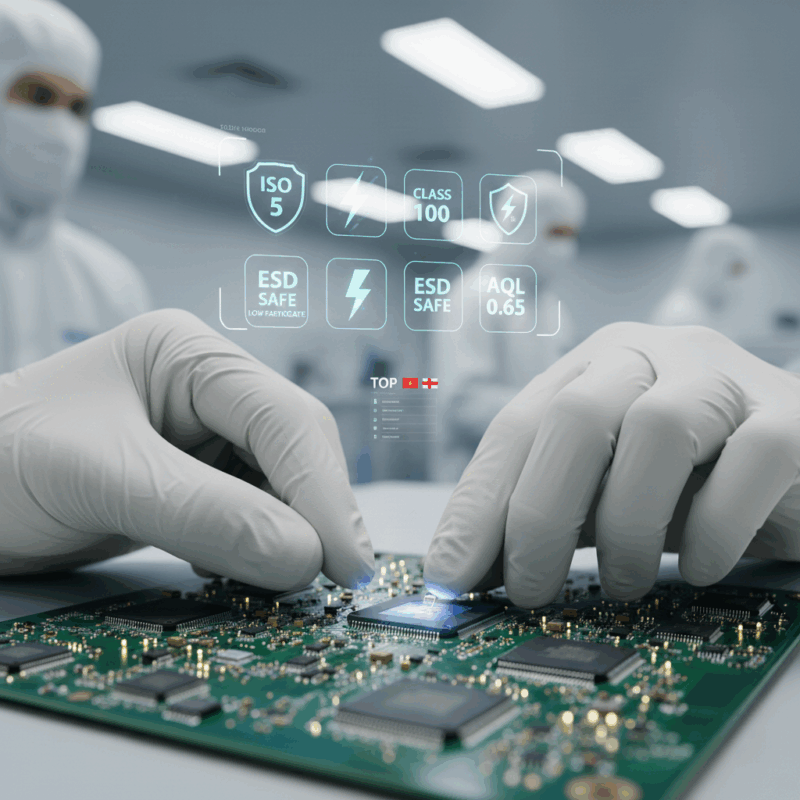

This comprehensive guide breaks down the Top 10 best cleanroom gloves specifically engineered for electronics manufacturing. We focus on gloves that excel in three core areas: ESD safety, ultra-low particulate count (ISO 5/Class 100), and superior barrier integrity (low AQL).

I. Defining the Non-Negotiables: Standards for Electronics Gloves

Before diving into the top models, understanding the core technical requirements is essential for procurement managers and quality engineers:

1. ESD Safety (Anti-Static Properties)

- Requirement: The glove must prevent charge build-up and safely dissipate static electricity to prevent damage to sensitive components (HBM, CDM).

- Key Spec: Look for gloves designated as ESD Safe with a Surface Resistance (Ω) typically falling in the range of 10 9 to 10 11 Ohms (or lower) and a low decay time.

2. Cleanliness Level (ISO 5 / Class 100)

- Requirement: Gloves must be processed and packaged in an environment that guarantees minimal shedding of particles, fibers, and residues.

- Key Spec: ISO 5 (equivalent to Federal Standard Class 100) processing is mandatory for most critical areas like wafer fabrication.

3. Barrier Quality (AQL)

- Requirement: The glove must be free from pinholes and defects.

- Key Spec: The industry gold standard for critical electronics is an AQL of 1.5 or lower. Ultra-premium gloves often achieve AQL 0.65.

II. Top 10 Best Cleanroom Gloves for Electronics Assembly and Fabrication

The following selection represents the best options available, ranked by their proven performance in critical electronics environments:

1. Ultra-Premium Nitrile ESD (AQL 0.65)

- Best For: Semiconductor front-end, high-end optics, and critical disk drive assembly.

- Key Specs: AQL 0.65, ISO 5, non-volatile residue (NVR) < 10µg/cm². Exceptional consistency.

2. Cleanroom Nitrile Class 100 (High-Performance)

- Best For: General microelectronics assembly, printed circuit board (PCB) handling.

- Key Specs: ISO 5, Powder-Free, Surface Resistance 10 9Ω/sq. Offers excellent balance of protection and cost.

3. ESD Safe Polyurethane (PU) Gloves

- Best For: Applications requiring extremely high tactile sensitivity (e.g., fine wire bonding).

- Key Specs: Highly transparent, thin profile, inherent ESD properties, suitable for ISO 6/7. Note: Less chemical resistance than Nitrile.

4. Glove Brand X: Class 100 Latex (Tactile Preference)

- Best For: Engineers who prioritize exceptional feel and grip over chemical resistance.

- Key Specs: ISO 5, high elongation, typically lower AQL, but poses an allergy risk. Always ensure it’s low-protein.

5. Cleanroom Nitrile with Textured Fingertips

- Best For: Increased grip for handling small, slick components or tools (e.g., tweezers).

- Key Specs: ISO 5, Textured finish on fingers, high chemical splash resistance.

6. Thai Hoa Nitrile Gloves

- Best For: Companies seeking a reliable, high-volume domestic or regional supply chain solution (Vietnam, SE Asia).

- Key Specs: ISO 5/6, ESD Compliance verified, highly competitive pricing for bulk orders, supporting fast local logistics. A strong option for sustained high-volume electronics manufacturing.

7. Cleanroom Neoprene Gloves

- Best For: Mixing chemical resistance and ESD needs (e.g., etching or plating processes).

- Key Specs: Superior chemical permeation rating compared to standard nitrile, often used as an outer glove.

8. 9-inch vs. 12-inch Cuff Length Gloves

- Best For: Varies based on need. 12-inch cuff is essential for full forearm coverage when overlapping with cleanroom suits/gowns.

- Key Specs: Always specify cuff length to ensure proper integration into the cleanroom garment system.

9. Heavy-Duty Nitrile (Thick Profile)

- Best For: Maintenance, handling rough tools, or processes where abrasion resistance is critical (sacrificing some tactile feel).

- Key Specs: 6.0 to 8.0 mil thickness, ISO 6/7.

10. Finger Cots (For Spot Applications)

- Best For: Isolating single fingers for very minor, quick adjustments outside the main line (e.g., non-critical repairs).

- Key Specs: Powder-free, rolled cuff, usually Latex or Nitrile materials. Used only when full glove donning is impractical or excessive.

III. Technical Deep Dive: Key Testing Protocols You Must Verify

When reviewing a datasheet for a glove intended for electronics, always look for verification of these specific tests:

A. ESD Performance Testing

The glove must pass testing protocols under ANSI/ESD S20.20 standards. Specifically, look for:

- Volume Resistance and Surface Resistance measurements. A value in the dissipative range (10 5 to 10 11Ω) is acceptable for grounding.

- Triboelectric Charging: The glove should generate minimal voltage when rubbing against other materials.

B. Particulate Testing (IEST-RP-CC005.4)

This protocol ensures the gloves release minimal particles and residue. Key metrics include:

- Non-Volatile Residue (NVR): Low NVR is vital for preventing films or residues on components that could affect coating or bonding processes.

- Ionic Contamination: Low levels of metal ions (Na+, K+, Cl–) are critical, as these can cause corrosion or electronic defects on micro-circuitry.

C. Pin-Hole Defect Testing (AQL)

The Water Leak Test (ASTM D5151) determines the AQL. For advanced electronics, never settle for an AQL higher than 1.5. The difference in manufacturing cost between AQL 2.5 and AQL 0.65 reflects enormous quality control efforts necessary to protect high-value electronic goods.

Conclusion: Protecting Yield with Precision

Selecting the right cleanroom glove for electronics manufacturing is a decision driven by data, not price alone. The ideal glove-often a certified Nitrile Class 100 with confirmed ESD Safe properties-acts as an invisible shield against product failure. By prioritizing models with ultra-low AQL, superior ESD control, and verifiable ISO 5 cleanliness, you significantly enhance your manufacturing yield and protect your bottom line.

Ready to upgrade your protective barrier? Click here to view the best deals and fast shipping options for certified ESD and Class 100 gloves!