In modern industrial environments — especially in cleanrooms and in the production of electronics, food, or pharmaceuticals — gloves are more than just protective equipment. The color of the gloves plays an important role in job classification, quality control, and enhancing worker safety.

1. Quick and Visual Job Differentiation

One of the greatest advantages of using multi-colored gloves is the ability to quickly and visually identify tasks and work areas. In large manufacturing facilities, employees often perform various duties:

- Handling sensitive components: Light-colored gloves are commonly used to easily detect dust or foreign particles.

- Cleaning and equipment maintenance: Dark-colored gloves may be preferred to hide stains and maintain a neat, professional appearance.

Color-coding helps reduce confusion, speed up production, and minimize the risk of contamination.

2. Contamination Control and Product Safety

In cleanroom environments, every detail — from hands to equipment — can be a potential source of bacterial or particulate contamination. Light-colored gloves help:

- Easily identify dirt, dust, or chemical residues on the glove surface.

- Detect tears or damage faster than dark-colored gloves.

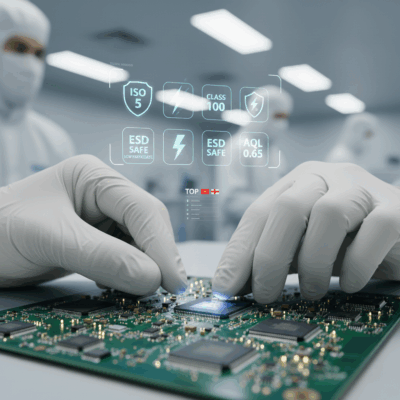

This is especially important for nitrile gloves or ESD gloves used in electronics manufacturing, where even a tiny particle can damage delicate components.

3. Enhanced Quality Control Efficiency

Supervisors or quality control technicians can identify employees’ work areas simply by the color of their gloves. For example:

- Blue: electronic component assembly areas.

- White: food or pharmaceutical processing zones.

- Black or gray: machine cleaning or raw material handling areas.

This system helps monitor the production process, reduce cross-contamination risks between zones, and enhance professionalism and safety standards.

4. Supporting Cleanroom Standard Compliance

Cleanroom standards such as ISO 14644 require strict contamination control. Using color-coded gloves not only helps distinguish job roles but also ensures compliance with contamination control requirements:

- Prevents confusion between ESD-safe gloves and non-ESD gloves.

- Helps identify gloves designated for specific cleanroom classes (e.g., Class 100, Class 1000, etc.).

5. Enhancing Workplace Aesthetics and Morale

Color is not only a technical factor but also affects workplace psychology and environment. A facility with a well-organized color system can:

- Help employees easily remember their tasks and assigned areas.

- Create a tidy, professional appearance.

- Reduce stress and confusion during work.

6. Key Considerations When Choosing Glove Colors

When selecting glove colors for cleanroom or production use, it’s important to consider:

- Company standards: Each glove color should have a specific meaning and be applied consistently.

- Material suitability: Nitrile, latex, and ESD gloves are available in various colors — ensure the chosen material meets requirements for anti-static, chemical resistance, or microbial protection.

- Visibility and detection: Light colors make it easier to spot dirt or damage, while darker colors help distinguish cleaning or maintenance zones.

Conclusion

Glove color in cleanroom and industrial manufacturing environments is not just about aesthetics — it’s a crucial factor for ensuring safety, contamination control, task identification, and compliance with quality standards.

A well-implemented color-coding system helps businesses reduce risks, improve efficiency, and maintain a professional working environment.